Optical Flats

Optical Flats

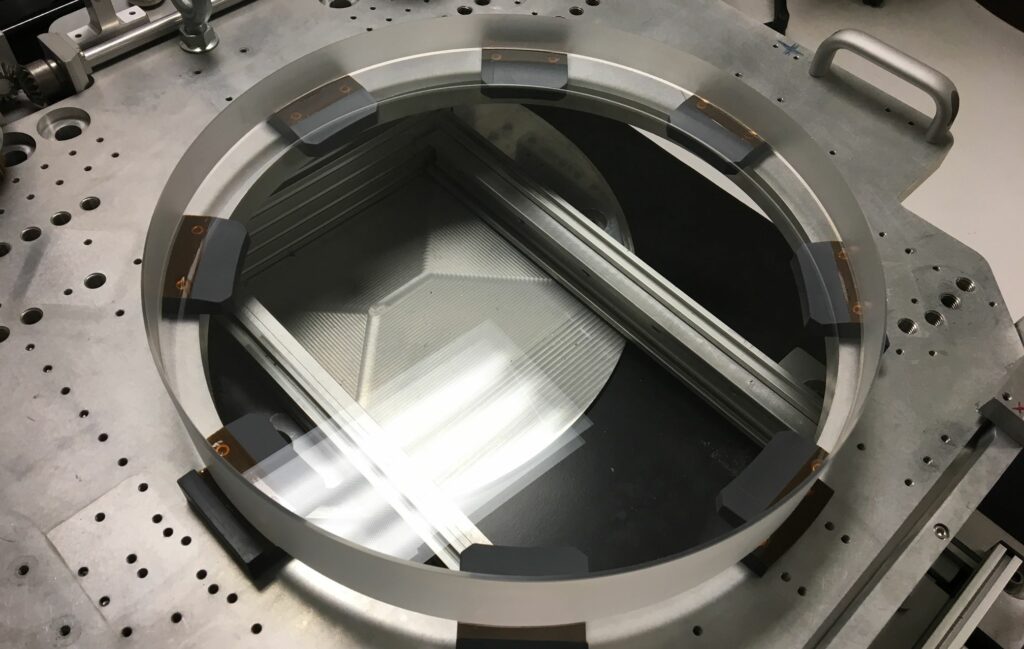

Precision Optical has been building high quality optical flats since 1959. Being naturally of a simpler geometry compared to prisms, a single-side or double-side polished optical flat has become a very consistent and deterministic optical component for us to manufacture.

With 28 continuous polishing laps, Precision Optical has capacity to handle the most demanding requirements for optical flats, wedges, mirrors and windows. From miniature Risley wedges to high-powered laser line mirrors to large interferometer flats, our experienced technicians produce optical components with superior flatness, transmitted wavefront, parallelism/wedge and mechanical dimensions, with minimal cosmetic surface defects.

When considering your optical flat, consider Precision Optical for coating to provide a turn-key coated optical flat. Our coating chambers are can be configured to handle optical flats ranging in size from 3mm to 660mm diameter. Coating capabilities include laser line, broadband and multi-band anti-reflection coatings, dielectric mirrors with high laser damage resistance, and plasma or ion enhanced dielectric coatings with excellent thermal stability. We also offer protected/enhanced aluminum and silver mirror coatings and neutral density filters.