Mechanical Testing

Mechanical Testing

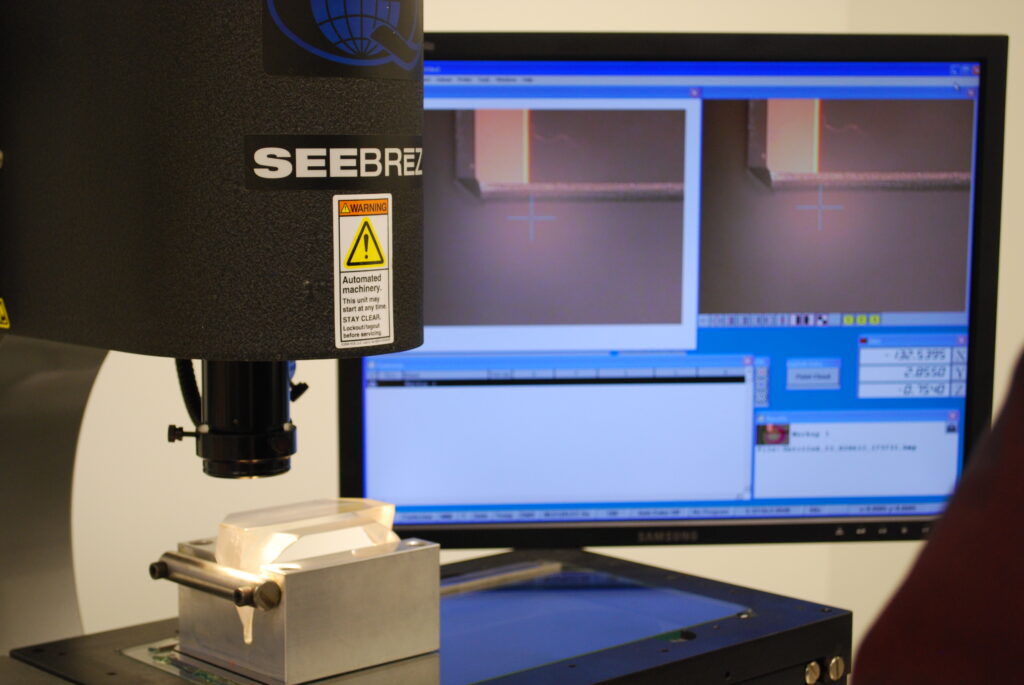

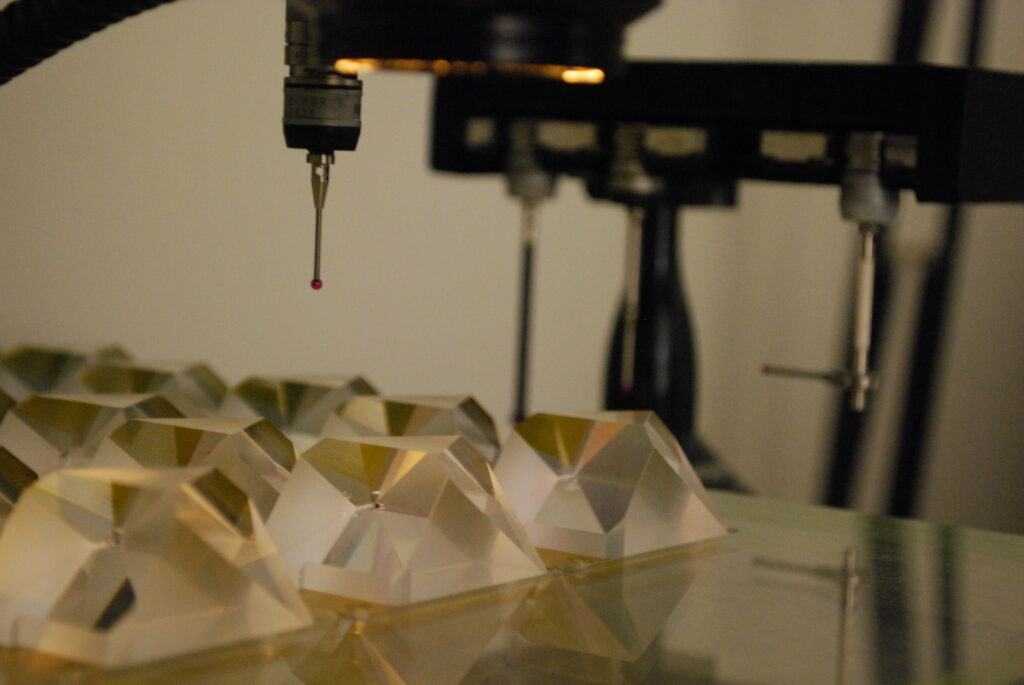

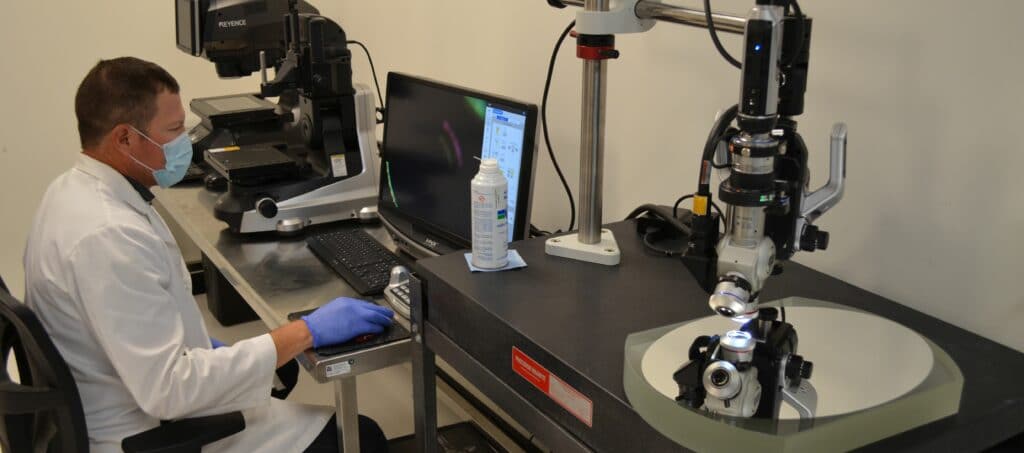

Precision Optical utilizes a broad range of mechanical inspection equipment to ensure accurate measurement and safe handling of optical surfaces. Our fully automated CMM (Coordinate Measuring Machine) equipment plays a central role in mechanical inspection due to its ability to perform many touch probe and optical measurements, which are used to calculate prism dimension. Our CMM’s provide accurate, minimally invasive measurements which are used to determine complex prism geometries, distances from theoretical apex to datum surfaces, critical sharp edge chip specifications and precise quantification of surface defects (scratch/dig).

Our CMM metrology is supported by an extensive variety of standard metrology instruments, including digital micrometers, drop gages, calipers, and optical microscopes. Our engineering team works closely with our machine shop to build custom fixtures, further enabling our mechanical inspection equipment to make precise measurements of intricate optical components.

Equipment |

|

|

|