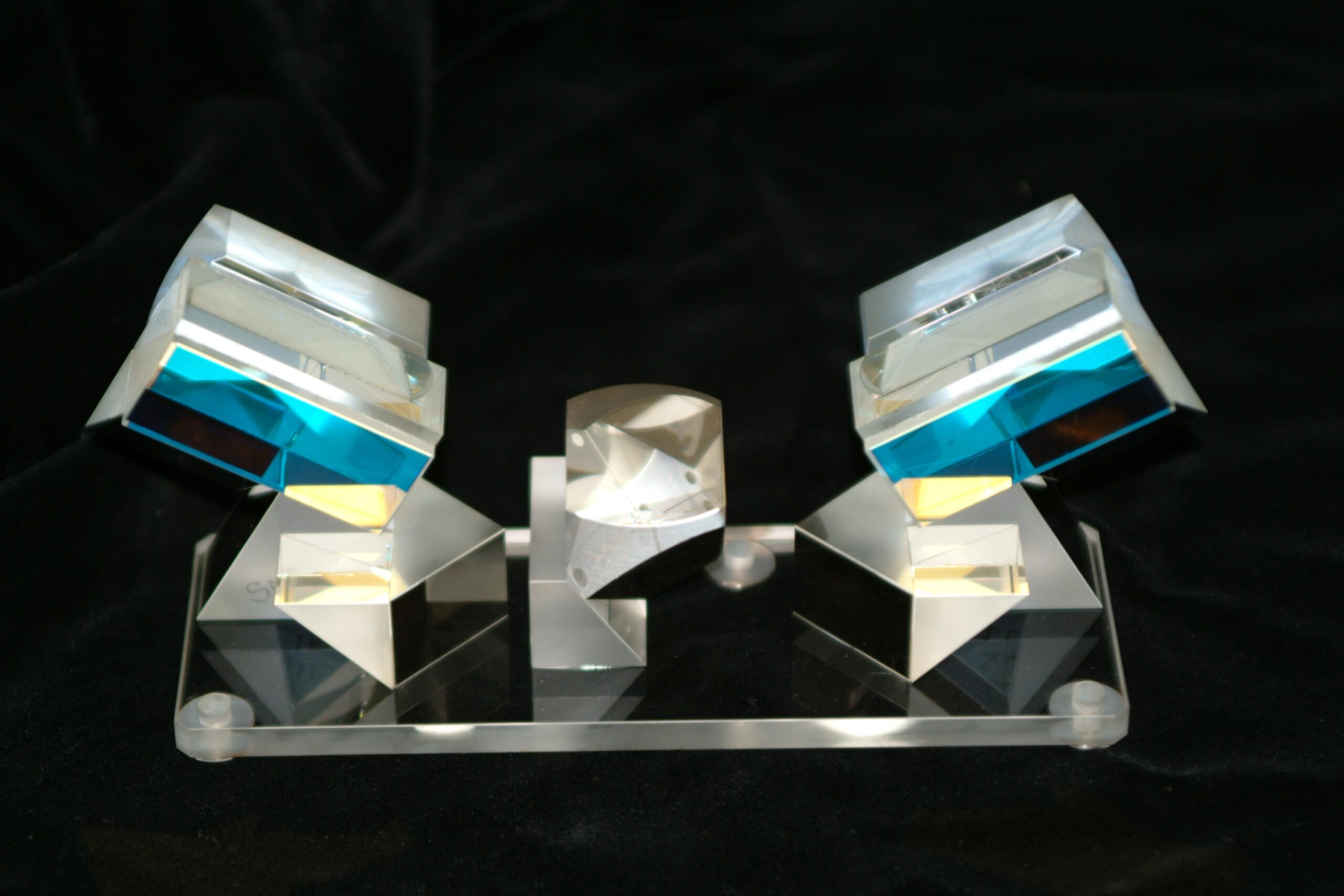

Assembly & Integration

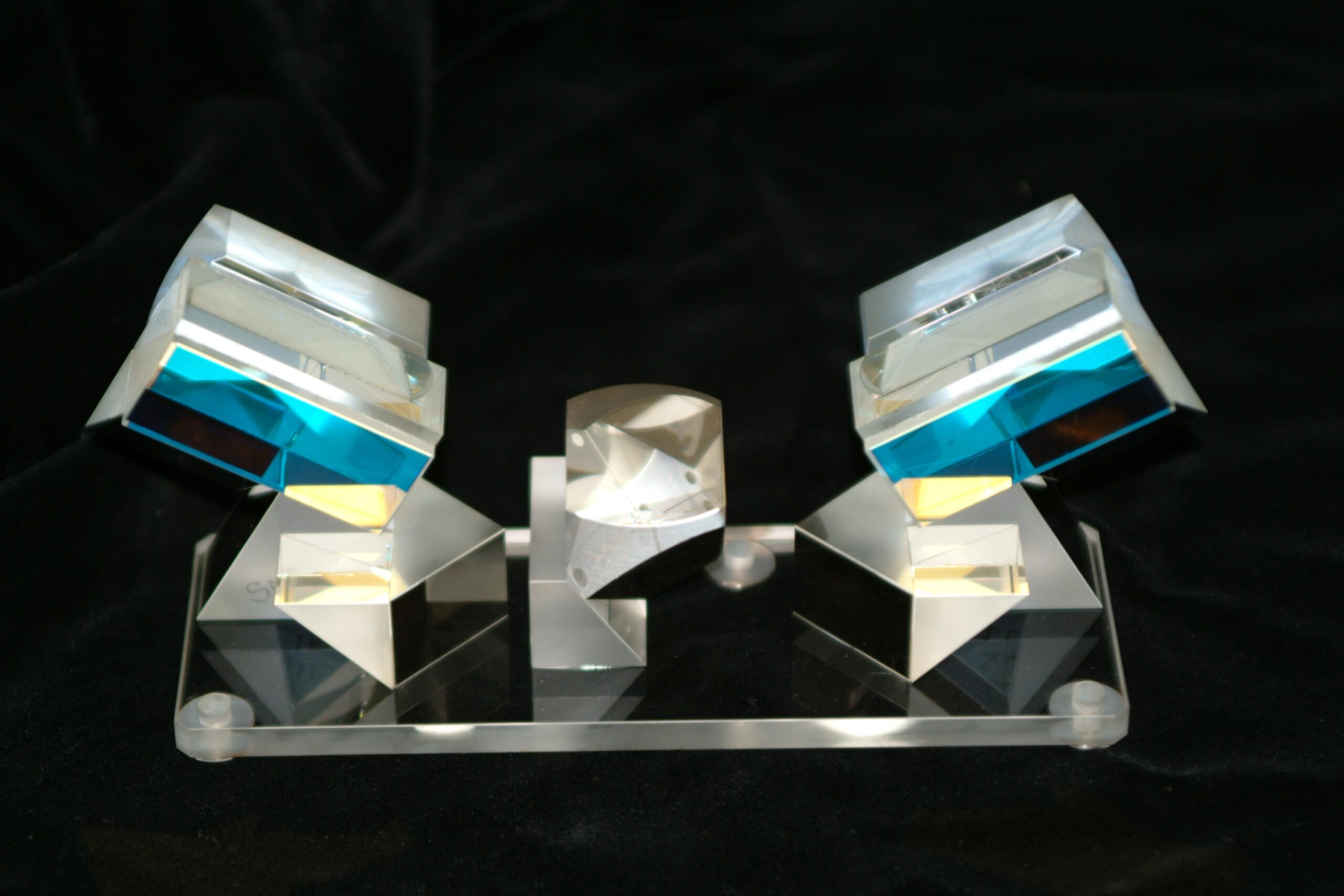

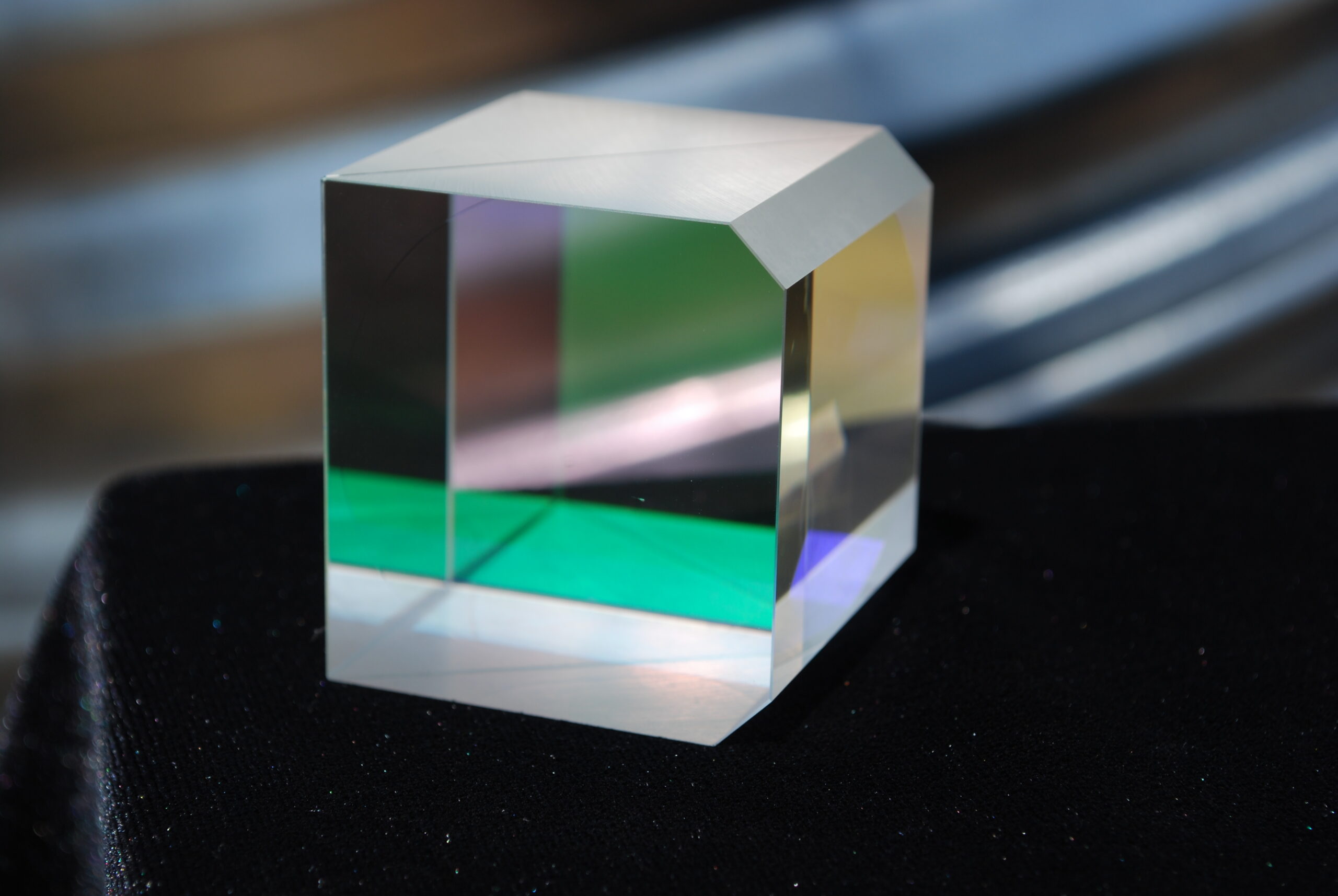

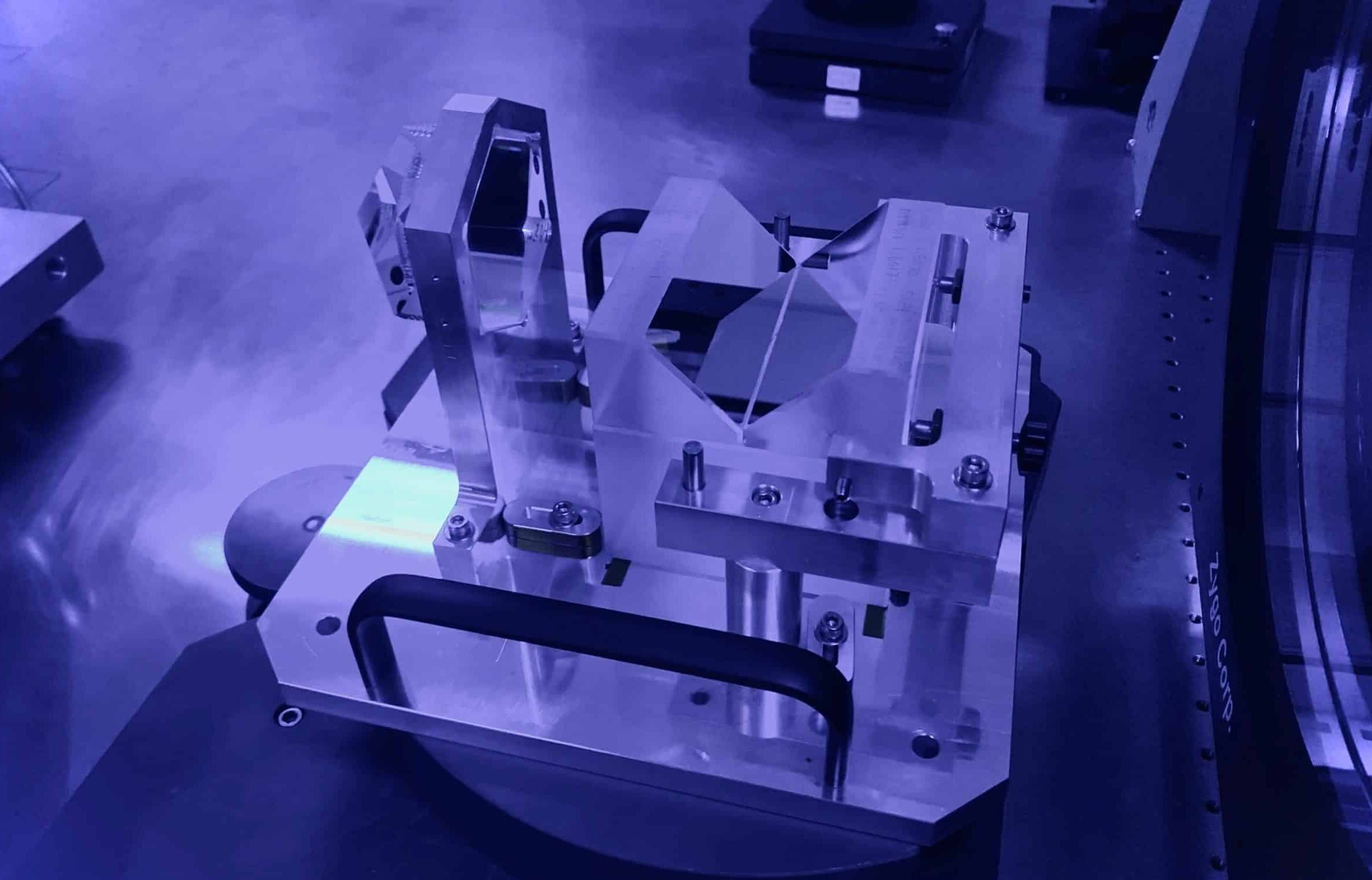

From standard cube beamsplitters to complex multi-prism assemblies, our experienced technicians produce clean, even bondlines that exhibit excellent optical alignment and environmental resistance. Our spacious assembly lab is configured for assembling a wide variety of prism shapes and sizes. Our engineering and sales team works closely with our customers to fine tune opto-mechanical assembly tolerances to balance budget vs. performance to support prototype to large volume quantities. Our CNC department provides in-house custom fixtures, which allows for precision alignment while minimizing contact with optical surfaces. Precision Optical’s optical assembly capabilities include:

- Cube beamsplitters, periscopes, wedge assemblies, penta prism assemblies, filter assemblies, pechan prisms with air gaps, erecting prisms, target reticles, and custom prism assemblies

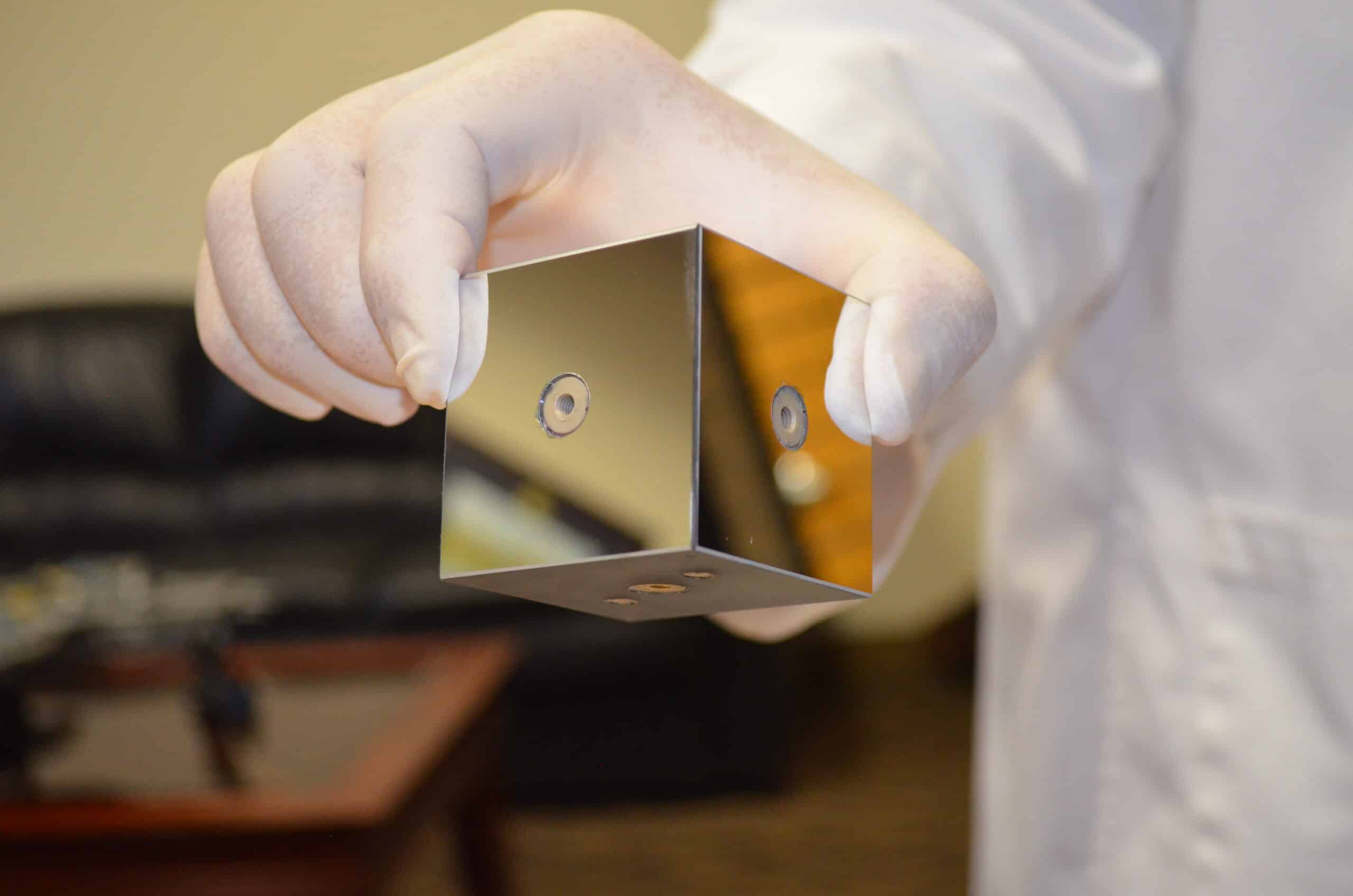

- Integration of optical components and optical sub-assemblies (potting) into/onto metallic frames & structures

- Experience with UV curing optical adhesives and optical epoxies for glass-to-glass bonding; as well as structural epoxies and silicone base RTV cements for glass-to-metal bonding

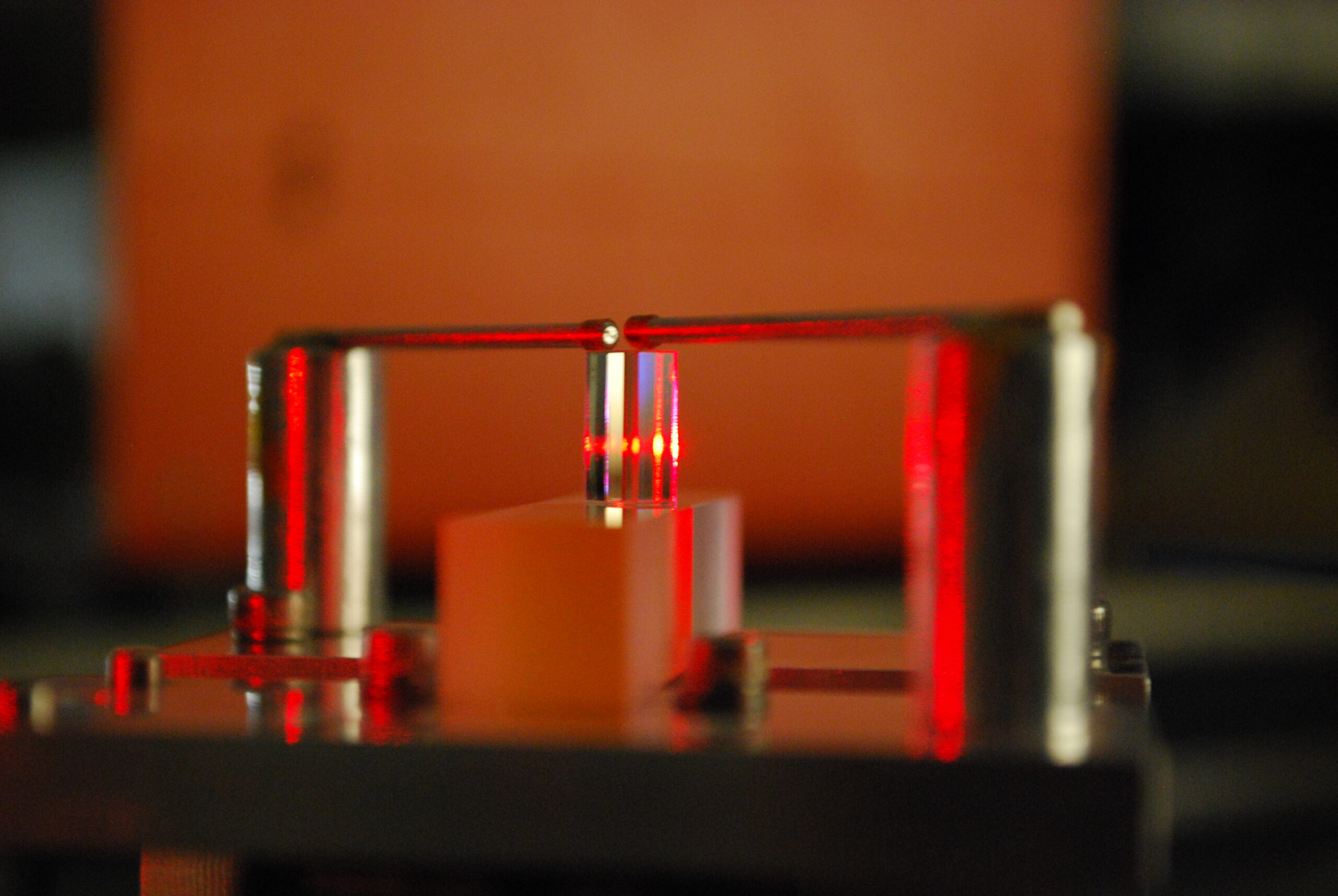

- Precise active optical alignment and/or physical positioning of multiple beam paths and prism components; including reticle location, position of focal planes, and alignment of laser insertion beams to line of sight beam paths

- Diffusion bonding of fused silica for monolithic prism assemblies such as precision hollow retroreflectors and adhesive-free beamsplitter cubes

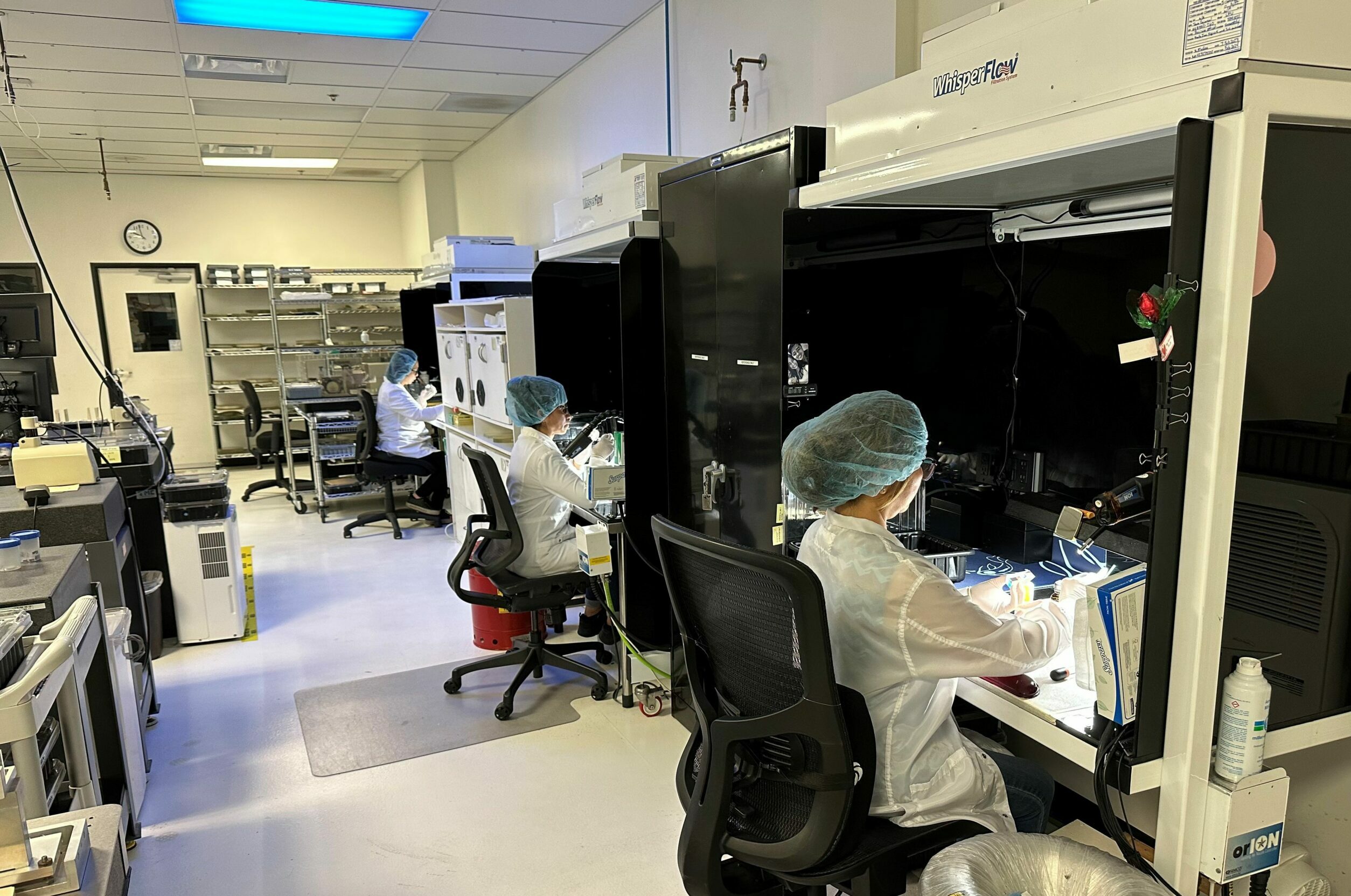

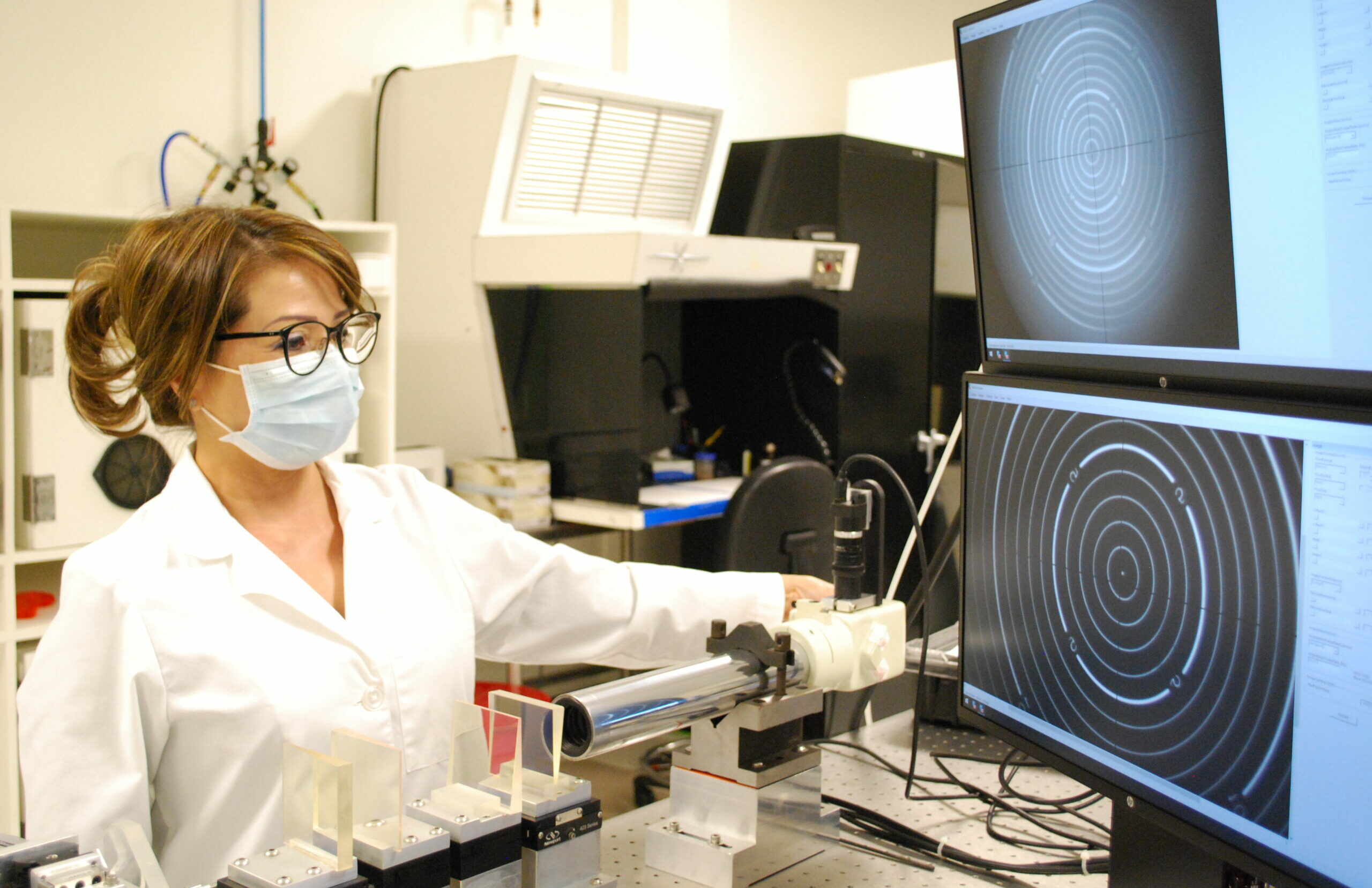

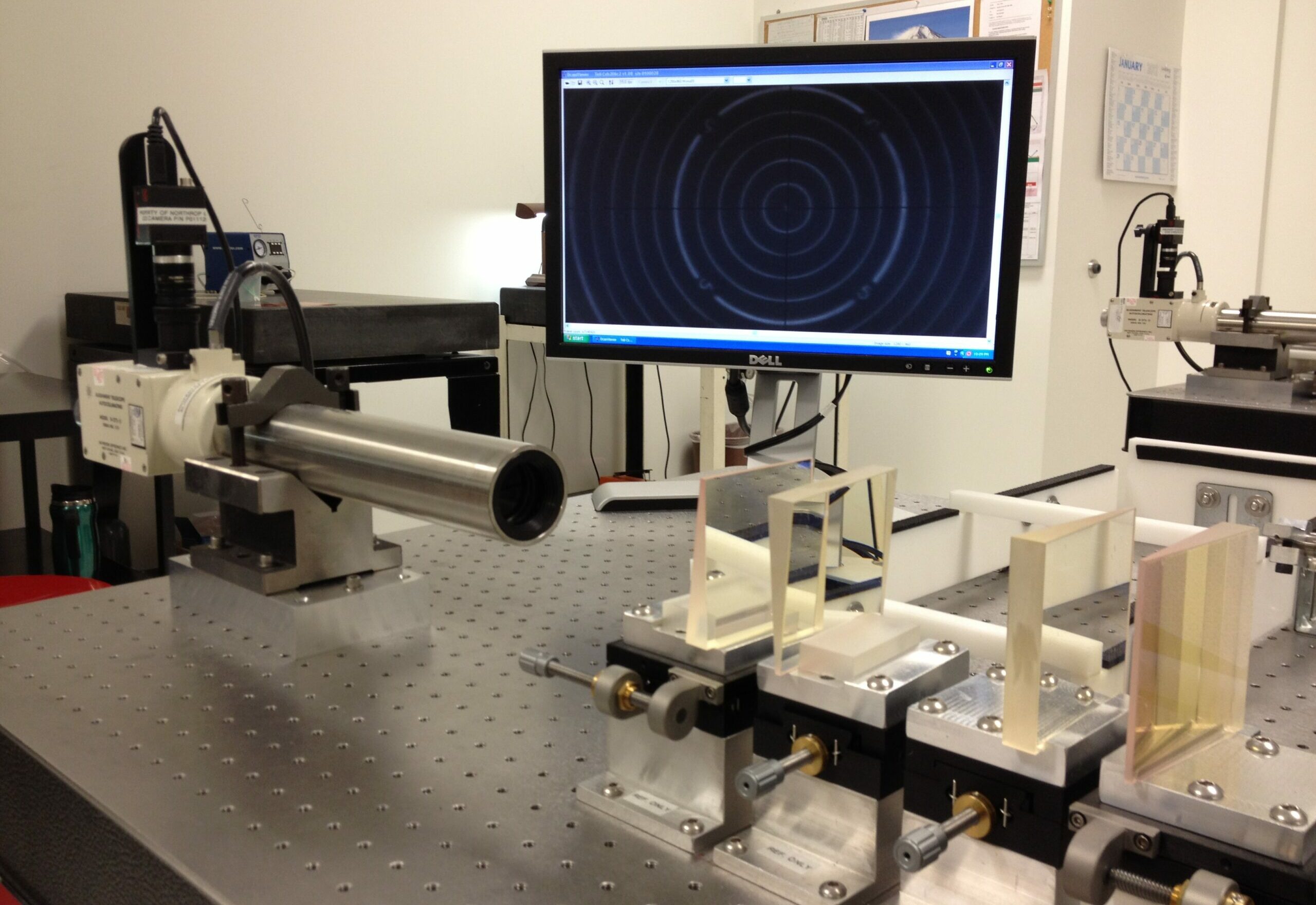

As an industry leader in optical assembly, Precision Optical is well equipped to meet our customers’ most critical alignment specifications. We utilize multiple designated and certified clean rooms (ISO class 7) and within each clean room we have certified laminar flow bench stations (ISO class 5). We have the following test and alignment equipment in our assembly laboratory:

- Zygo GPI-XP phase shifting interferometer with MetroPro 9 upgrade and 101.6mm aperture (640 x 480)

- Multiple Davidson D-602 autocollimators

- Multiple Nikon autocollimators with universal positioning stands

- Multiple Davidson D-279 alignment telescopes

- Custom mounted digital cameras for collimators and alignment telescopes

- Custom and modular alignment tooling

- Multiple Newport & TMC vibration/isolation tables

- Multiple wavelength UV curing stations

- Centrifuges for properly mixing of optical adhesive

- Numatic adhesive dispensers for structural epoxies

- Nitrogen purged optics storage bins

Get a Quote for Assembly & Integration

Typical Specifications |

|

|

|

Testimonials

Donald A. Pearson II

Äpre InstrumentsI am always very happy with Precision Optical. Their lead times and delivered product are excellent. I wish more of our suppliers were like Precision Optical!

Brian Monacelli, Ph.D.

Laser Technology Professor - Pasadena City CollegePartnering with Precision Optical through their Ensign-Lambert Optics Education Program has allowed over 120 of my laser and optical technology students to gain real-world perspective with hands-on work in optics. These interactions directly motivate the next generation of technicians as they learn first-hand how this fascinating work with industrial hardware will translate into rewarding careers.