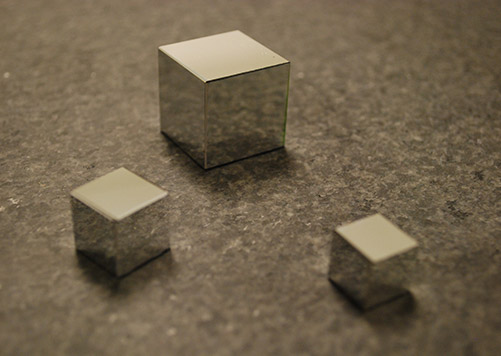

Alignment Cubes

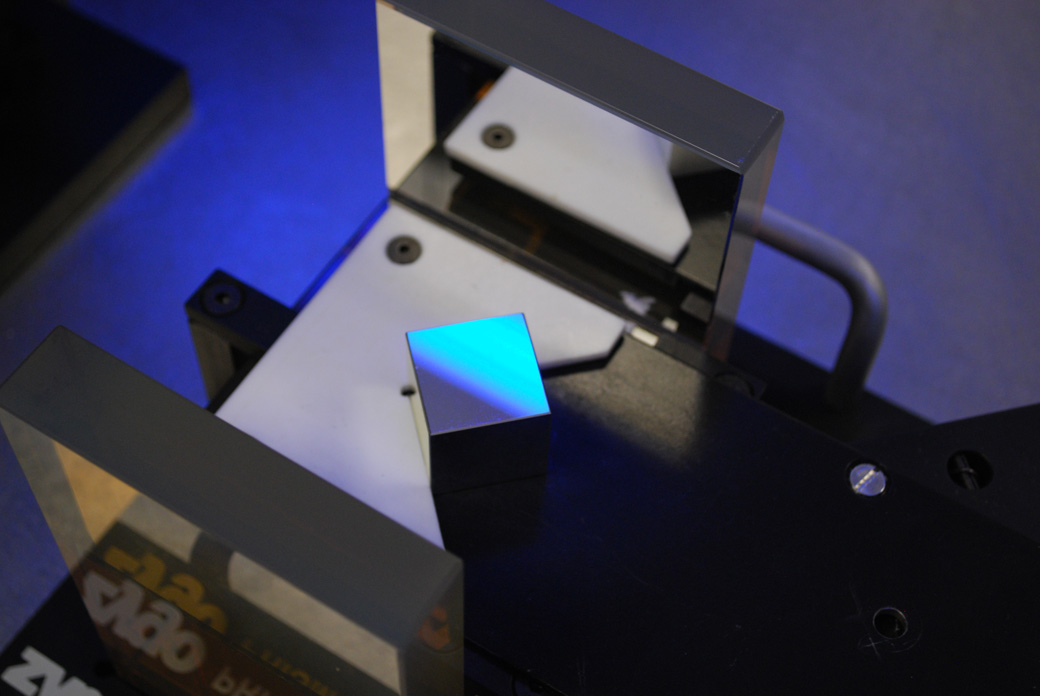

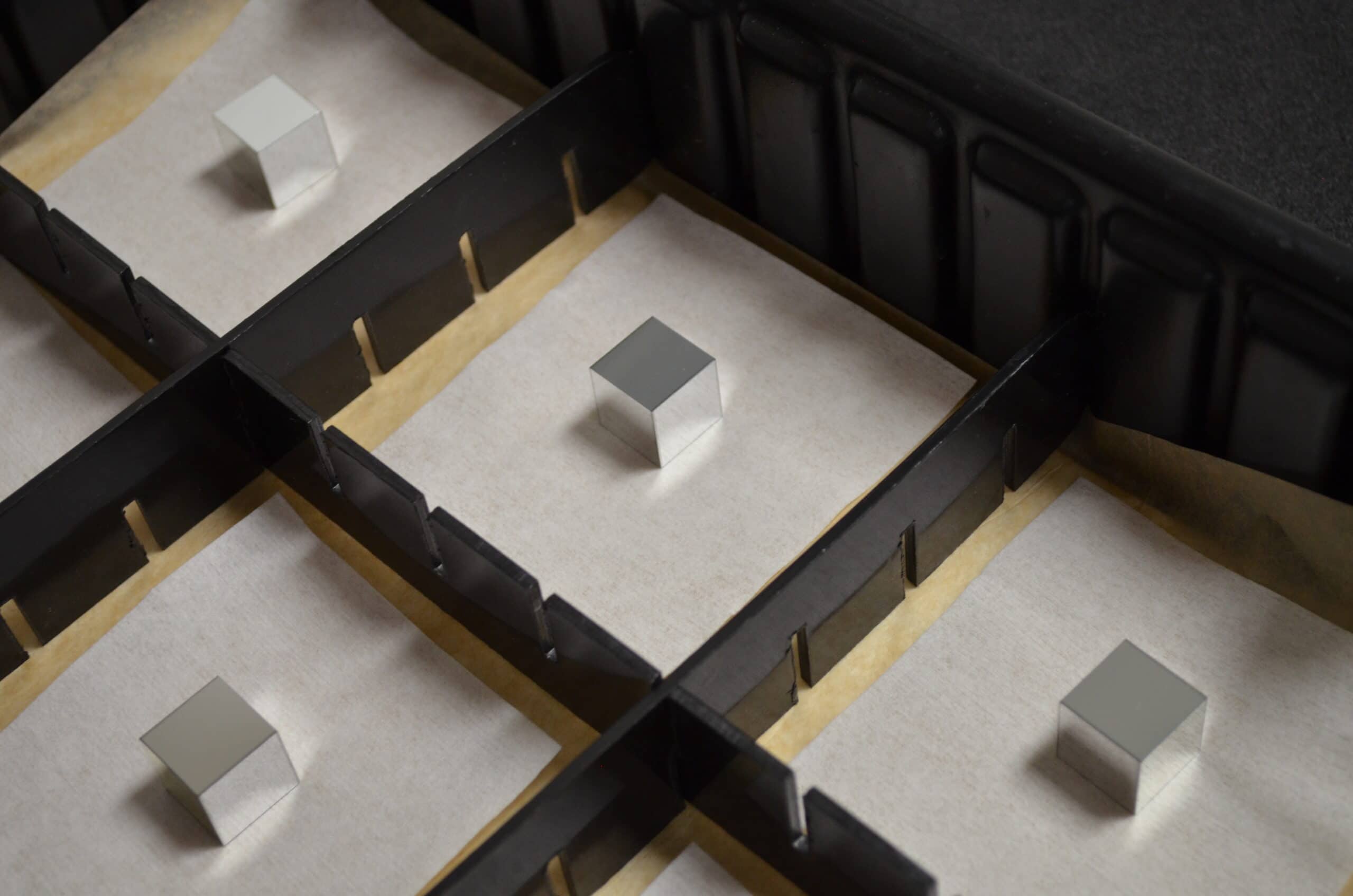

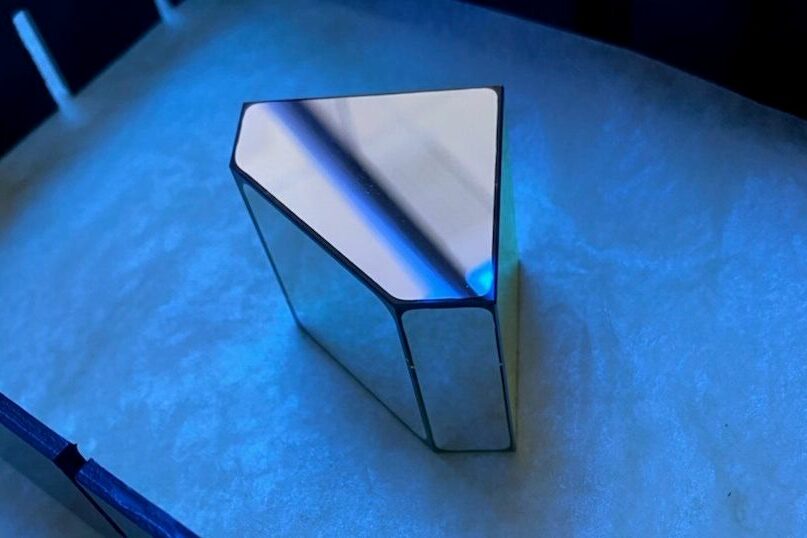

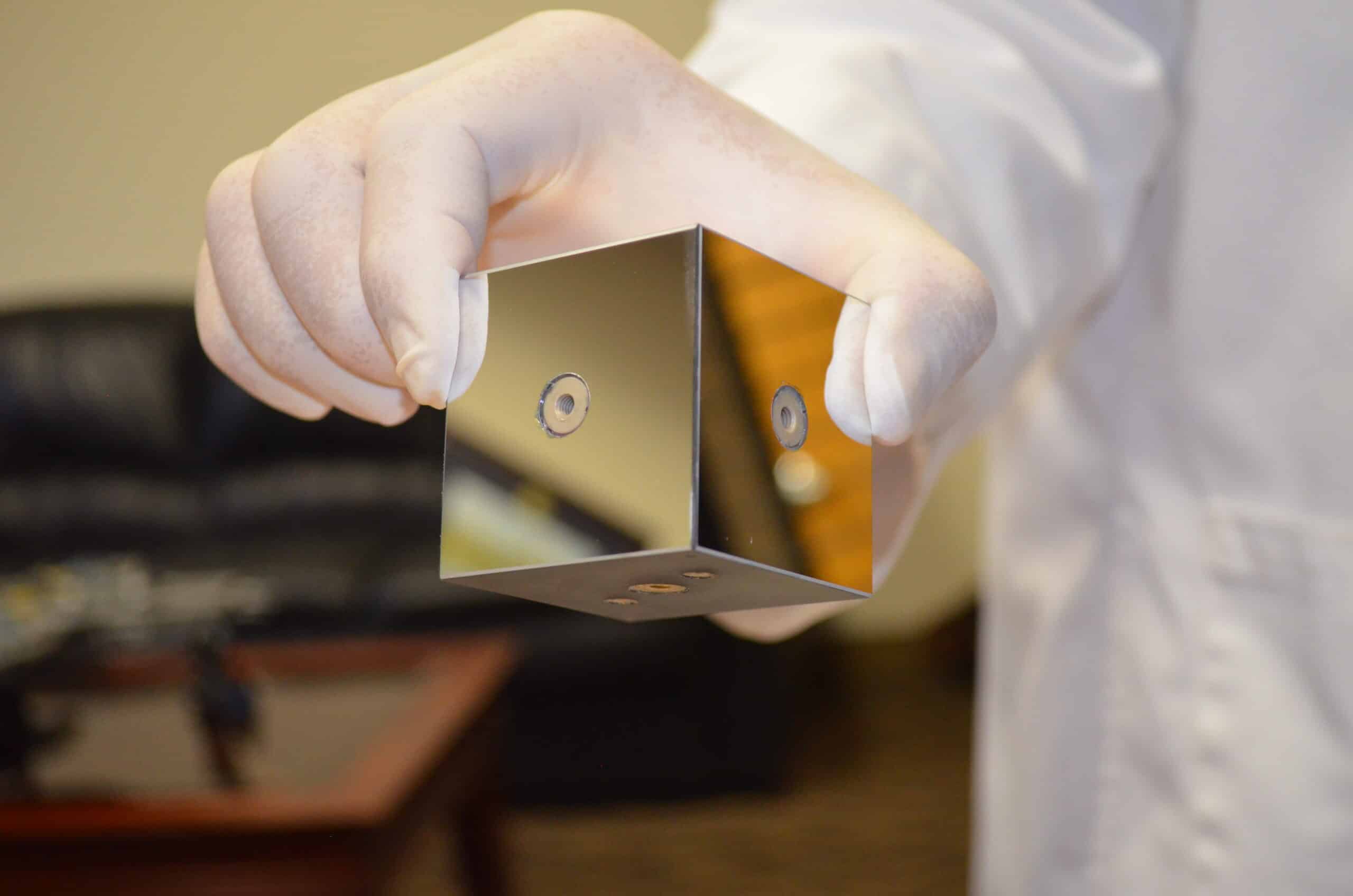

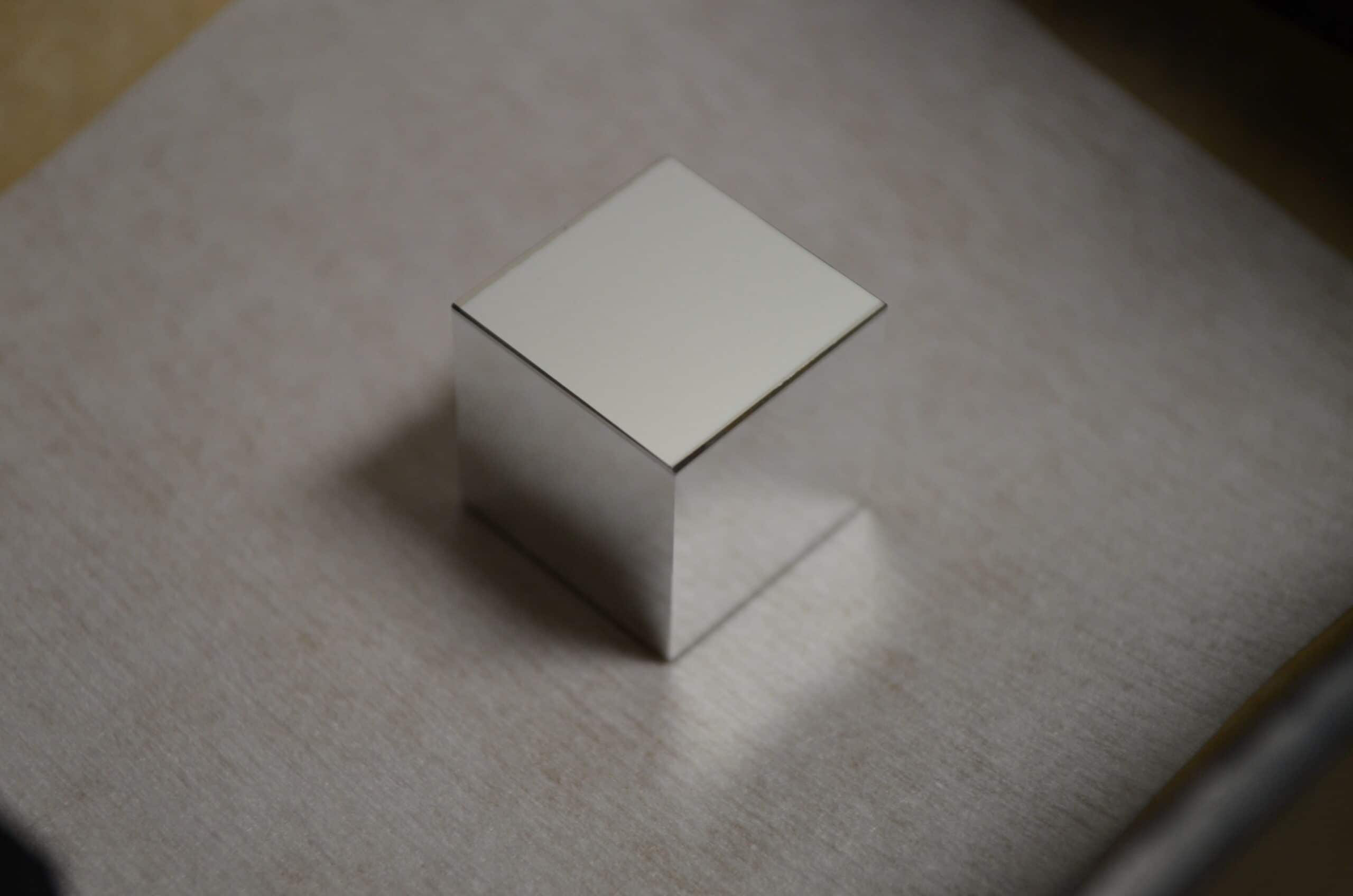

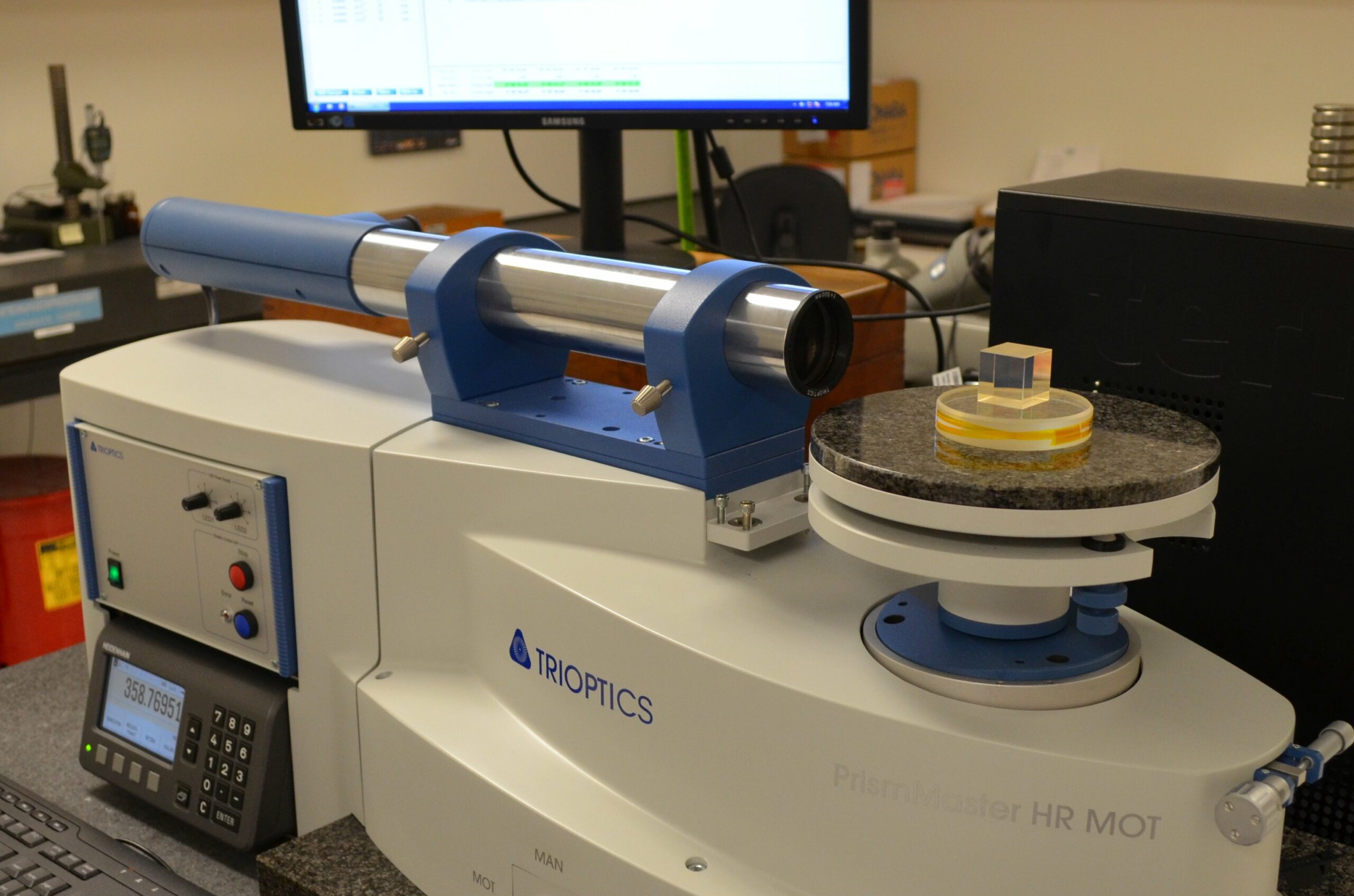

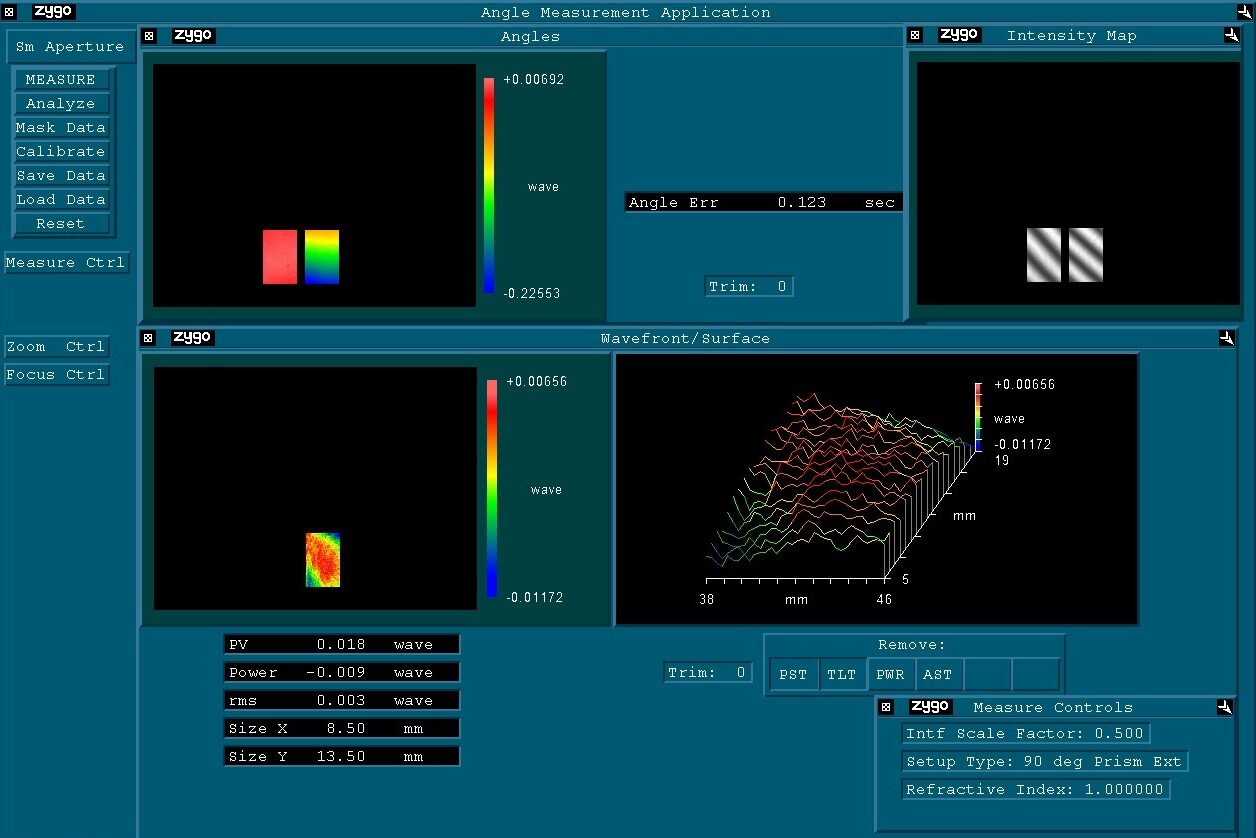

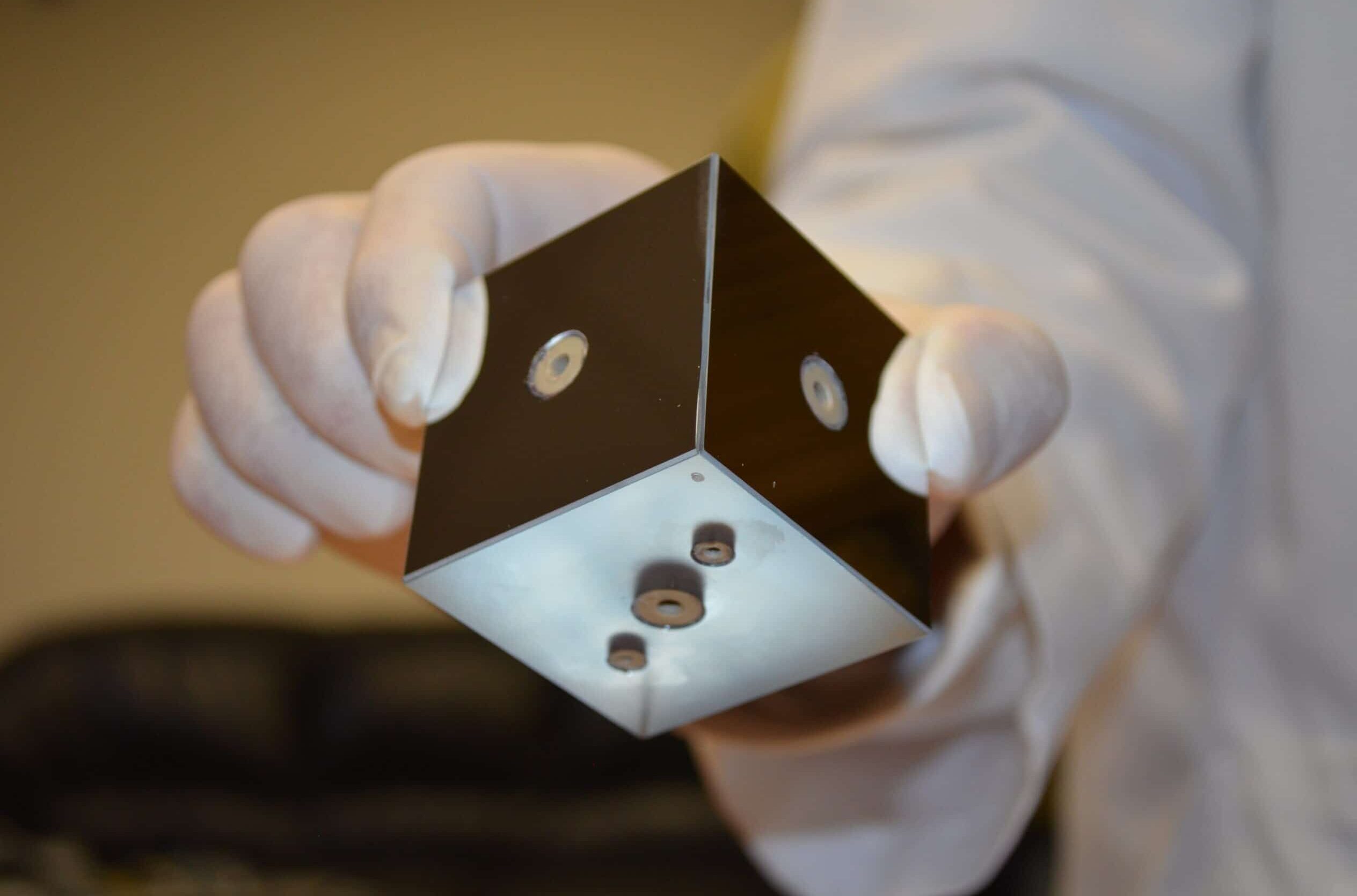

Optical alignment cubes are used to monitor and qualify systems where critical optical alignment is necessary. Precision Optical offers standard and custom sized optical alignment prisms with precision angles in several glass types as well as stainless steel. For extreme temperature applications, materials such as Zerodur and fused silica are optimal choices due to their low thermal expansion coefficients.

Our optical alignment cubes are polished on five surfaces and coated with a durable protective aluminum mirror coating. Upon request, the base of the prisms may be bonded to custom mounts or outfitted with threaded bushings. Alignment cube assemblies and custom prism geometries are also available.

See our attached (PDF) catalog drawing for our high end alignment cubes.

Get a Quote for Alignment Cubes

Typical Specifications |

|

|

|