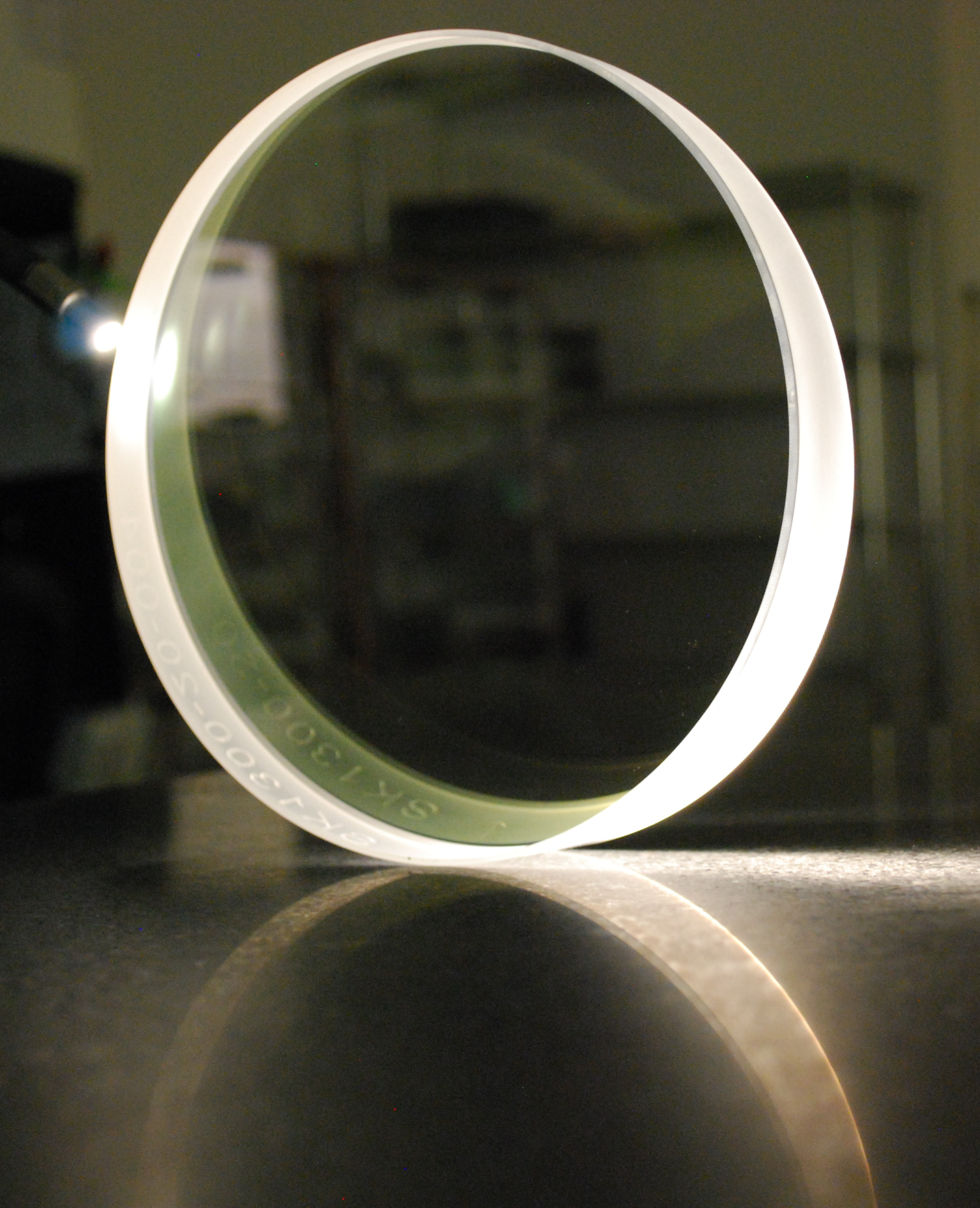

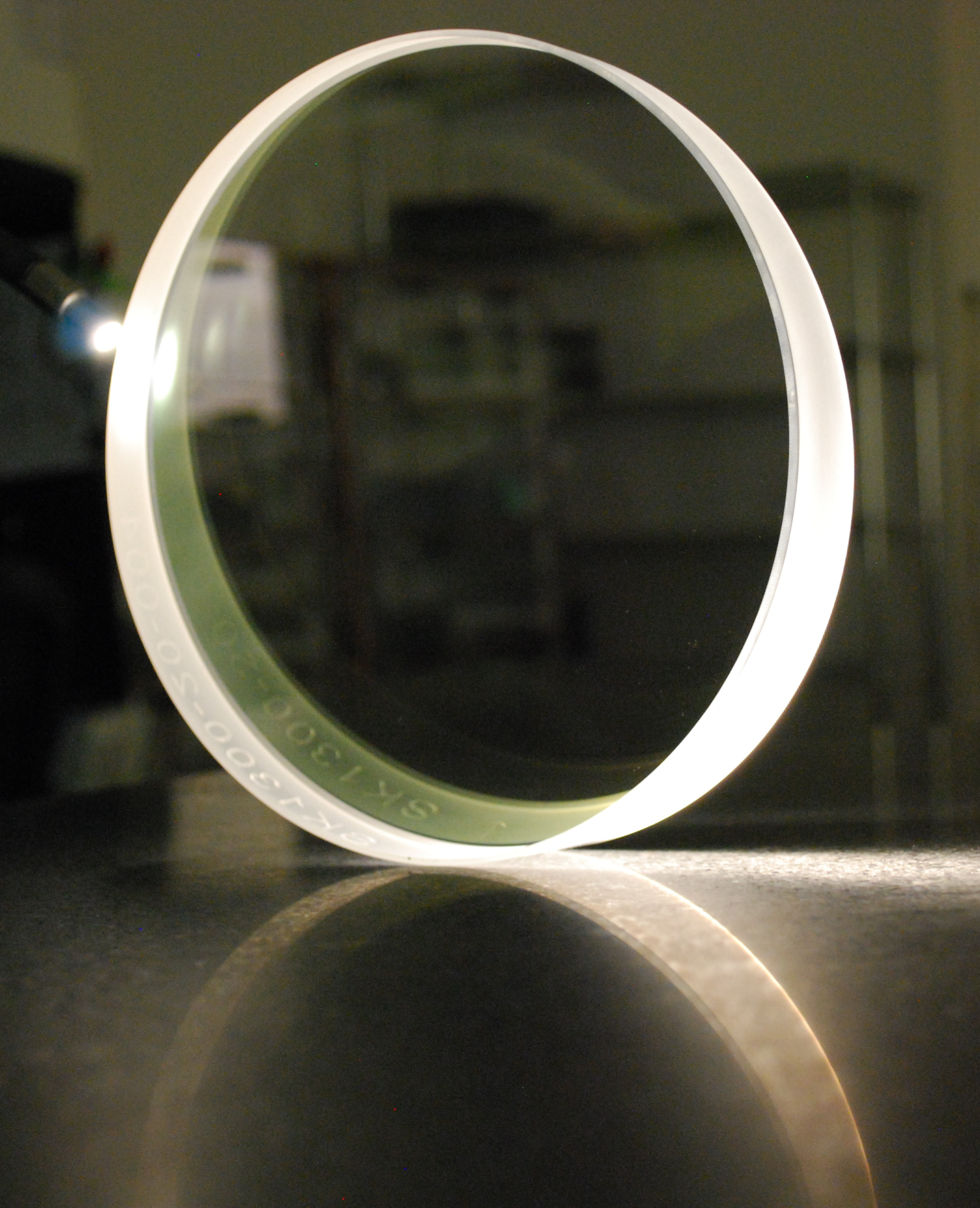

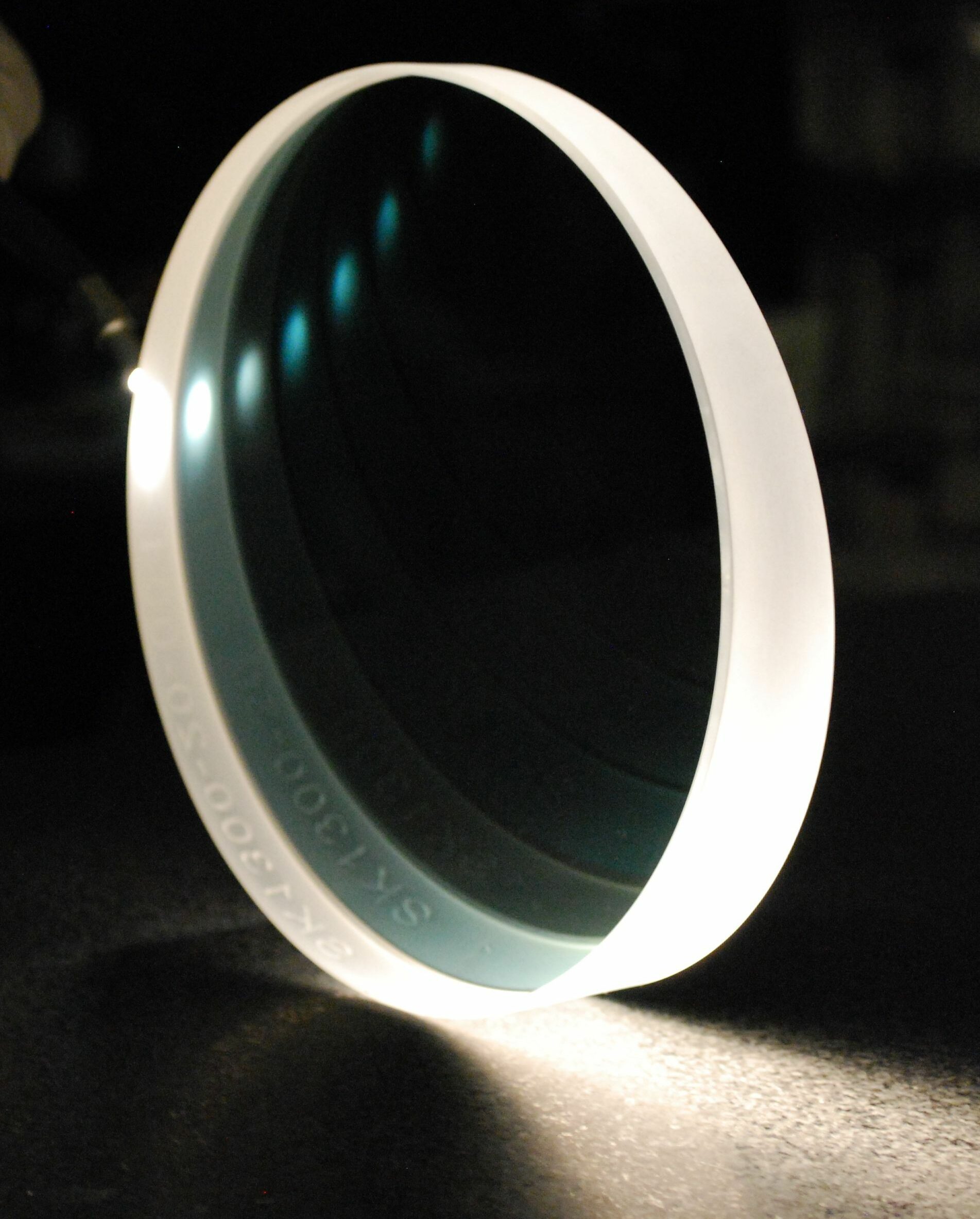

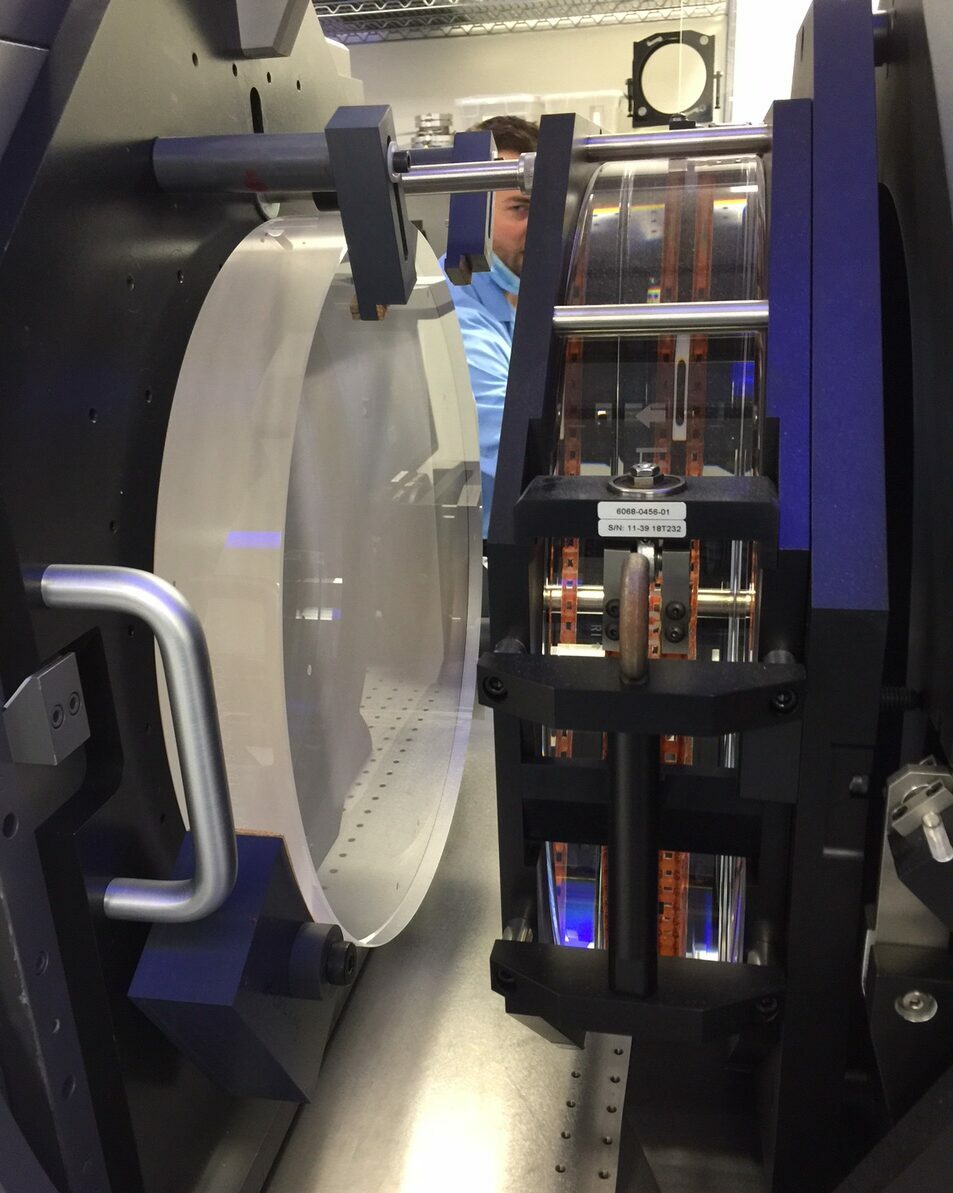

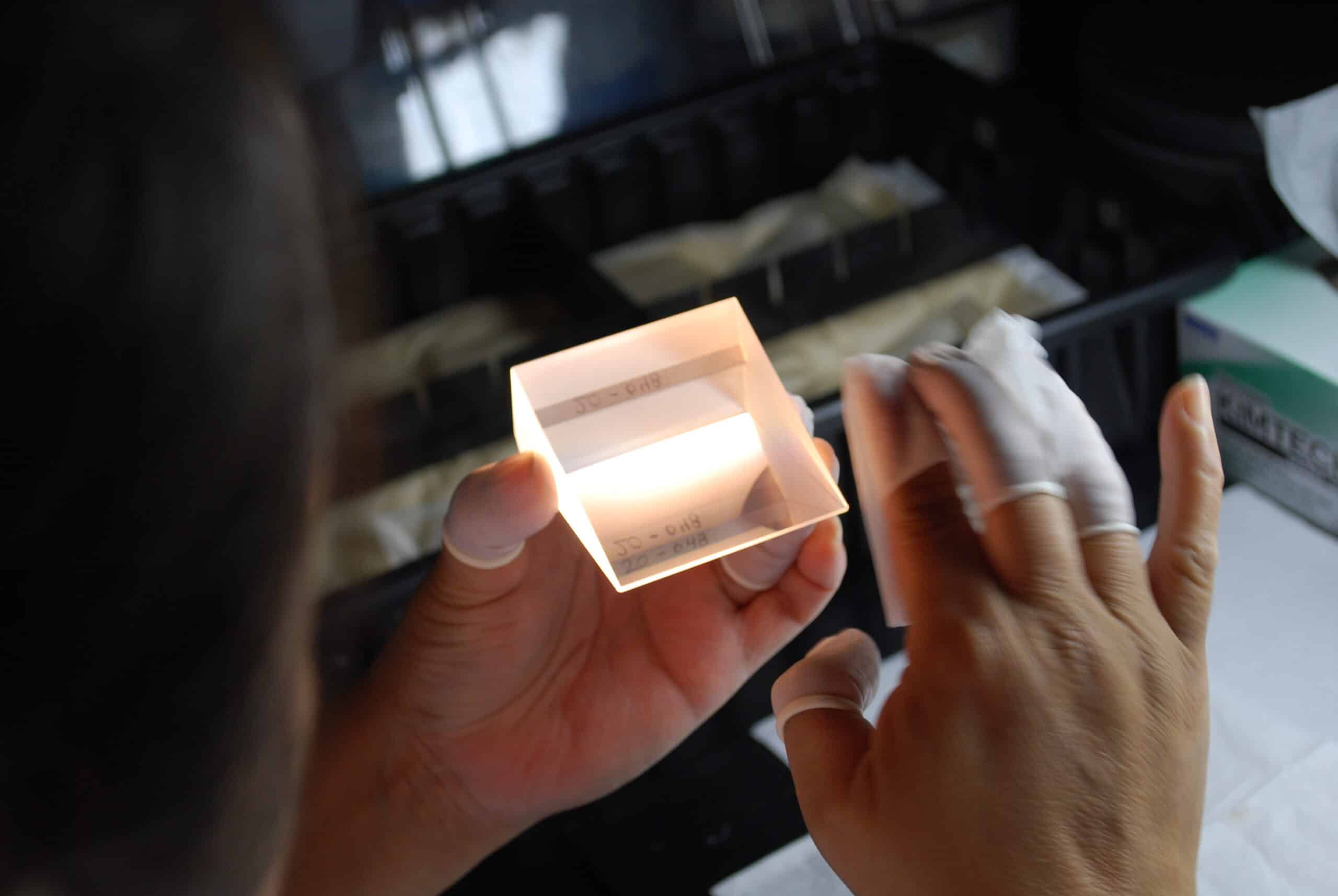

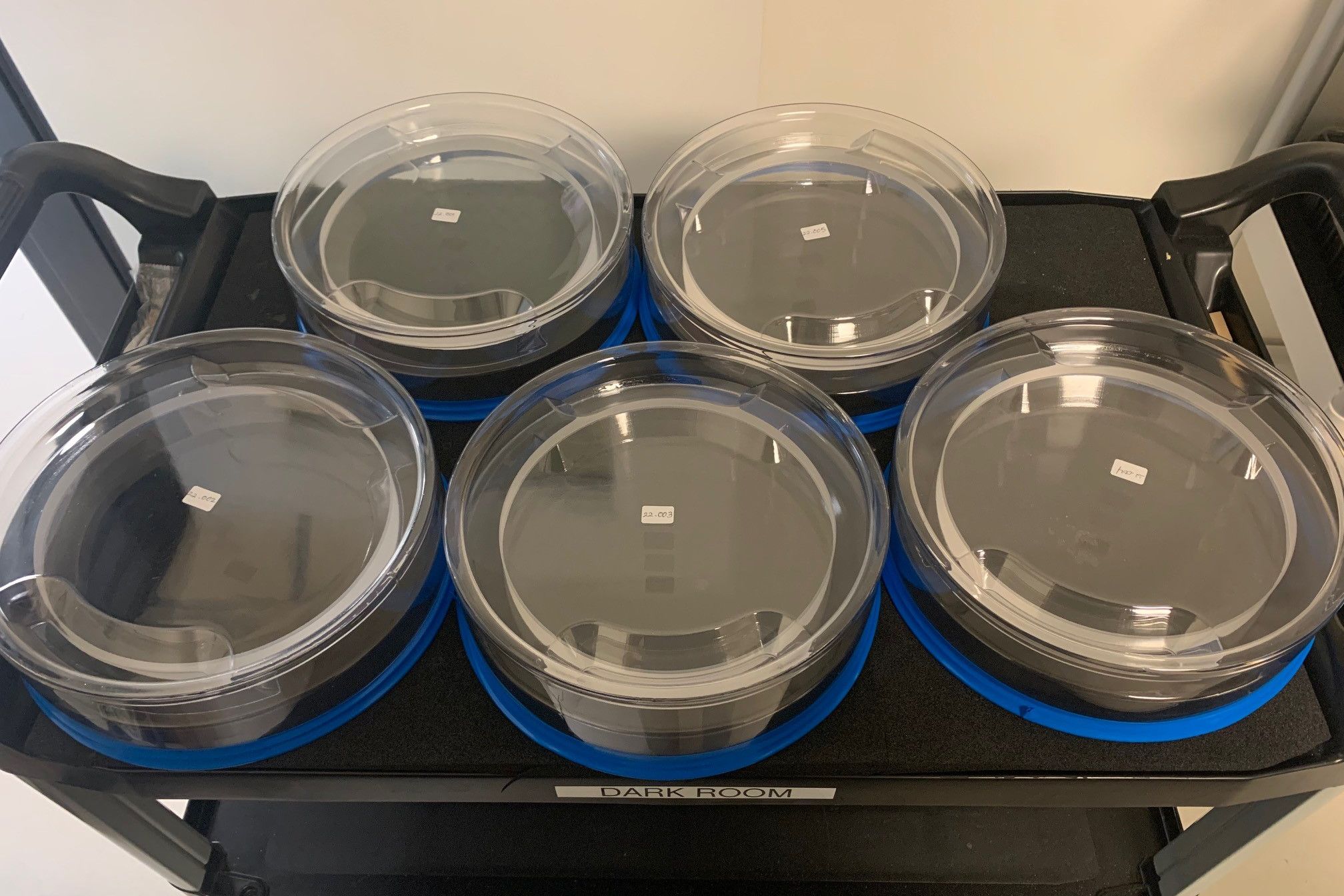

Optical Flats and Wedges

A wedge variant of an optical flat will have at least one of the optical surfaces wedged with respect to the opposite optical surface and/or a periphery edge. Our typical size range of optical flats and wedges is 50mm to 500mm, but we can accommodate smaller or larger optical flats.

We typically build optical flats and wedges to customer-driven specifications and drawings. However, Precision Optical is fully capable of helping our customers design their optical flat or wedge in a manner to help balance budget vs. performance and feasibility.

Many optical flats that we produce are considered reference flats, and are critical for metrology instruments and applications where a reference surface establishes the accuracy of the instrument. These optical flats are typically extremely flat. We can offer unmounted reference flats such as this in surface accuracies from lambda/4 PV (or PVr) to lambda/60 PV (or PVr). For certain aperture sizes, we can mount the reference flat within a metallic cell that adapts to industry standard interferometer bayonets. Please see our mounted reference flats page for more details.

In most cases, Precision Optical will supply the substrate glass material (and coatings) as a turn-key optical flat solution. However, in certain cases, we will accept customer furnished material and perform the necessary operations as a service to bring the optical flat into specification. In some cases, an optical flat has been damaged and a customer would like the optical flat repaired and refurbished to its previous condition.

Many optical flats do not require thin film coating. Some customers choose to coat optical flats themselves, or outsource the coating to a 3rd party supplier. Precision Optical is pleased with any level of business opportunity, and we are very open to providing the best all-around solution for each customer. If a coating supplier is specifically recommended to us, we would be happy to use that supplier and provide a turn-key coating solution that meets the customer request.

One of the best recommendations we can provide would be for Precision Optical to coat the optical flat or wedge in-house. We have dramatically increased our coating capability and capacity over recent years and also provide coating as a separate service for customer furnished material.

Get a Quote for Optical Flats and Wedges

Typical Specifications |

|

|

|

Testimonials

Donald A. Pearson II

Äpre InstrumentsI am always very happy with Precision Optical. Their lead times and delivered product are excellent. I wish more of our suppliers were like Precision Optical!

Brian Monacelli, Ph.D.

Laser Technology Professor - Pasadena City CollegePartnering with Precision Optical through their Ensign-Lambert Optics Education Program has allowed over 120 of my laser and optical technology students to gain real-world perspective with hands-on work in optics. These interactions directly motivate the next generation of technicians as they learn first-hand how this fascinating work with industrial hardware will translate into rewarding careers.