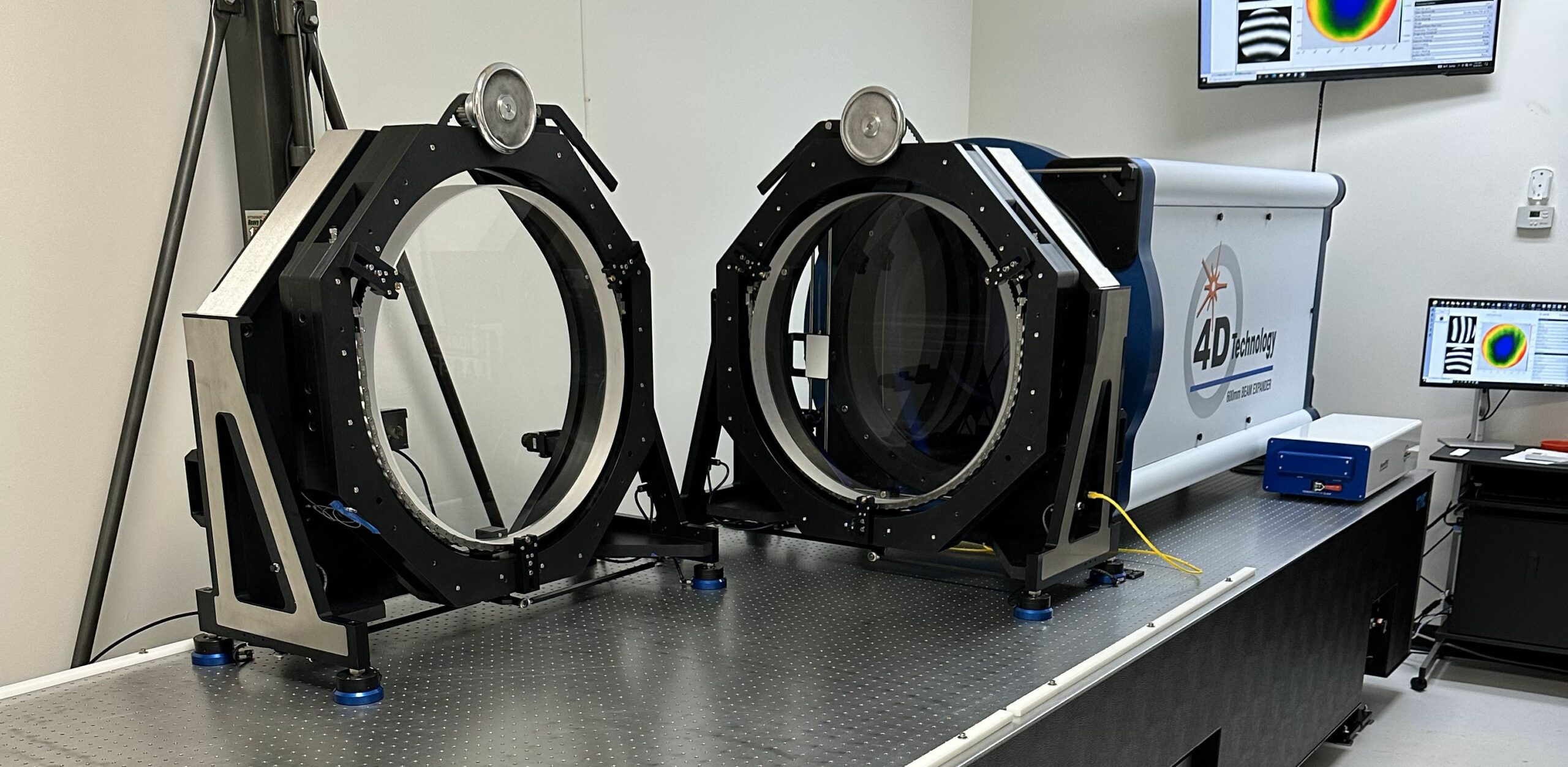

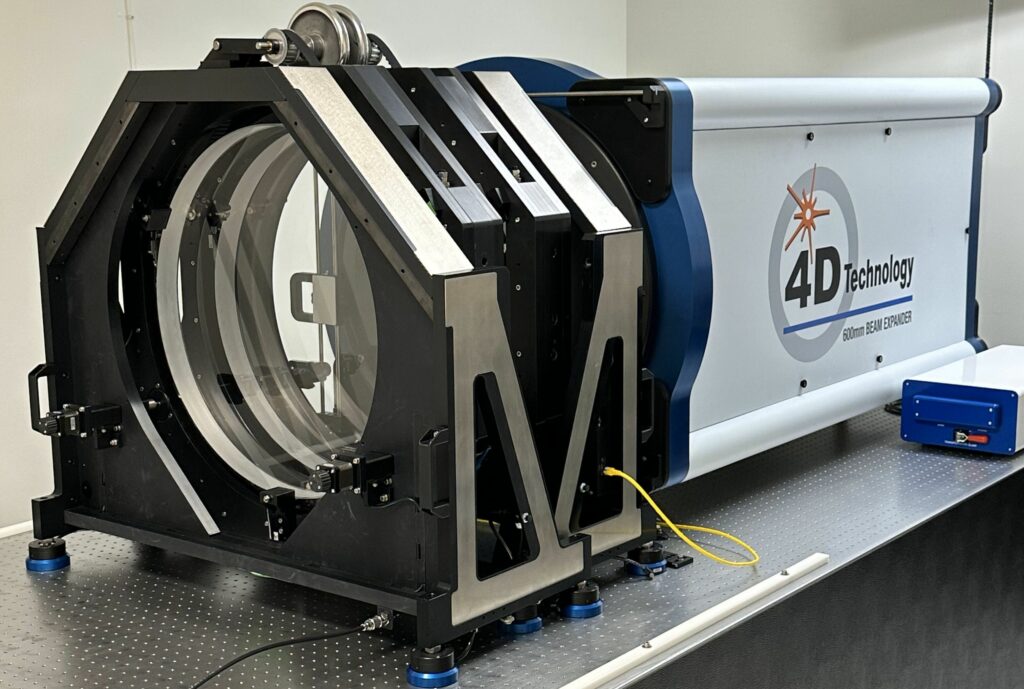

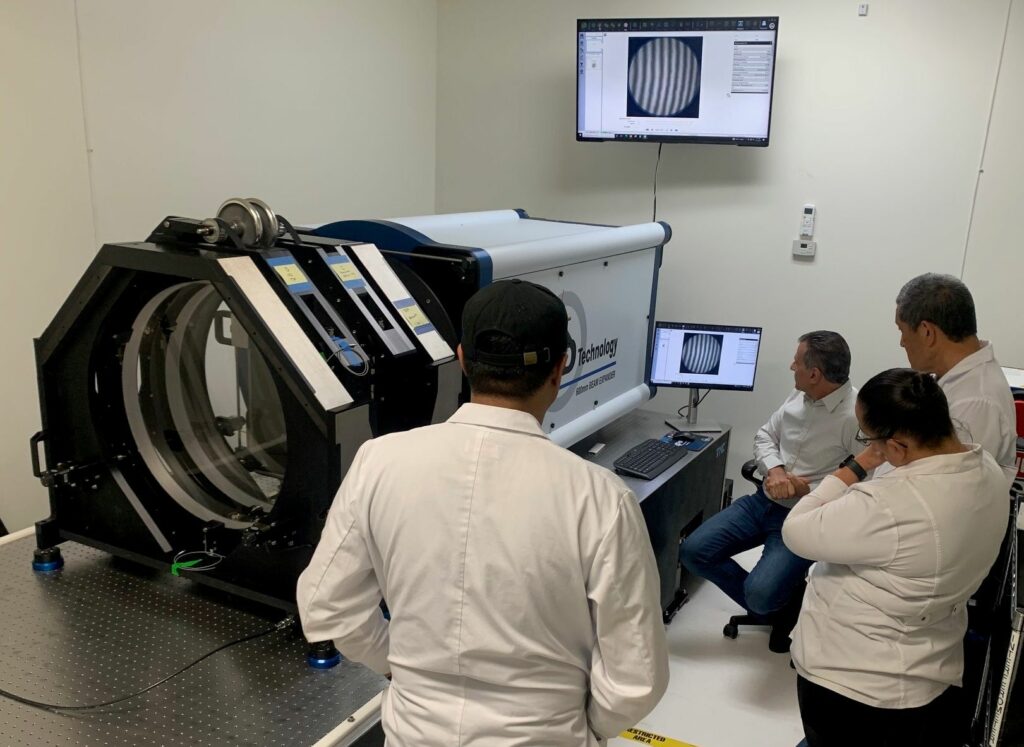

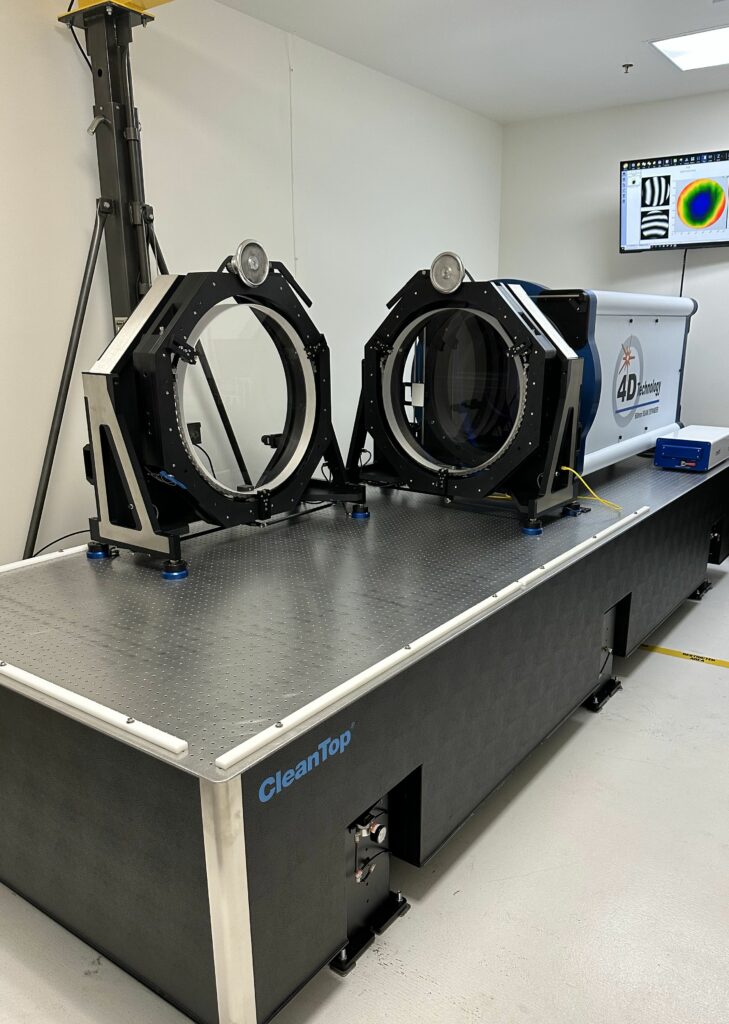

Precision Optical maintains a of host metrology capabilities, including precision goniometers, spectrophotometers, surface profilometry, 1064nm inspection, and dual 450mm aperture laser interferometers. But our new on axis dynamic AccuFiz-D has a short-coherence 638nm source, enabling up to 2 meters of path matching capability. We have utilized this fantastic technology for over 10 years using our 4D FizCam 2000, however our aperture has always been limited to 150mm. We can now path match optical surfaces, cavities and beam paths over 600mm diameter apertures.

This drastically improves our ability to measure surface form of parallel optical flats or large complex prisms without having to diffuse rear surfaces with paint or lacquer (a side effect of long coherence sources and often temporal phase shifting interferometers). In addition, we can measure direct optical cavities of certain substrate configurations. This allows us to extract transmitted wavefront error (TWE) data without having to pass thru the optical element in a double-pass configuration, thereby speeding up the measurement process and improving measurement accuracy.

We will be able to inspect glass inhomogeneity via two methods: the traditional 4-measurement method (empty cavity, TWE, S1 & S2) or with an improved 3-measurement method (empty cavity, TWE, & S1/S2 cavity). These methods will also be more efficient as each individual measurement can be acquired virtually independent of vibration and turbulence.

Precision Optical has customized this system by building some of our own optical components. In particular, we have fully manufactured our own 600mm transmission flats. We have customized their optical performance as well as their coatings and the 4D mounting hardware in order to provide a large bandwidth of measurement functions. Most notably, this will enable full contour 3-flat testing, allowing us to calibrate articles up to 600mm and moving us closer to our goal of becoming ISO certified for calibration.

Lastly, we will combine this equipment and technology with our own custom suspension hardware capable of inspecting and stitching up to 800mm test optics in both transmission and reflection with remote digital tip/tilt controls.