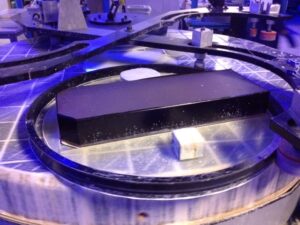

Precision Optical has been manufacturing optical flats since 1959. However, over the last decade, the amount of large optical flats and windows (>300mm) we have manufactured or serviced has dramatically increased. Frequently, optical flats require re-surfacing. This is a service that Precision Optical provides, and in most cases we are able to accomplish return delivery within 2 weeks of material receipt. Many large optical flats require coating of one or more surfaces. With our 480mm diameter coating capability, we are able to coat large optics and preserve the surface quality and surface form of the optical surfaces.

Precision Optical has been manufacturing optical flats since 1959. However, over the last decade, the amount of large optical flats and windows (>300mm) we have manufactured or serviced has dramatically increased. Frequently, optical flats require re-surfacing. This is a service that Precision Optical provides, and in most cases we are able to accomplish return delivery within 2 weeks of material receipt. Many large optical flats require coating of one or more surfaces. With our 480mm diameter coating capability, we are able to coat large optics and preserve the surface quality and surface form of the optical surfaces.

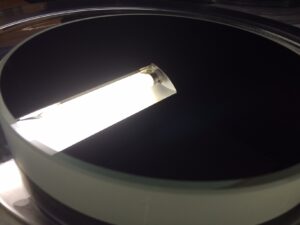

We can grind and polish optical surfaces up to 735mm in diameter. We can kinematically hold large flats up to 520mm in diameter (digital tip/tilt) and inspect over 450mm apertures using laser interferometry. With typical geometries/materials we can regularly achieve < lambda/20 for both surface flatness and surface irregularity and 10-5 surface quality. We also have experienced great success with producing reference flats and the mounting of large optical flats.

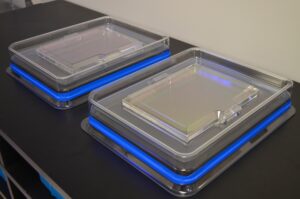

From January through August of 2015, Precision Optical has delivered over 100 large flats (>300mm) and reference flat optics to variety of customers. Most of these large flats required thin film coating, rigorous metrology inspection, and custom packaging solutions.

With a combination of a highly skilled work force, plenty of capacity, high-end large aperture metrology, thin film coating and assembly capability, Precision Optical can be your “one-stop shop” for large optical flats and windows. Please contact us for more information!