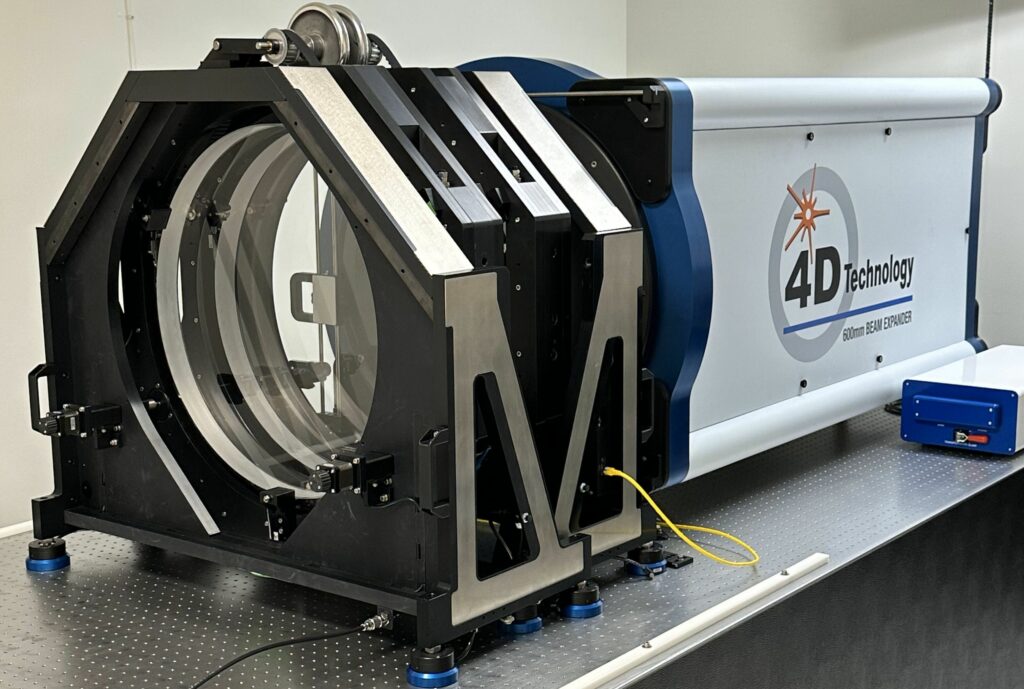

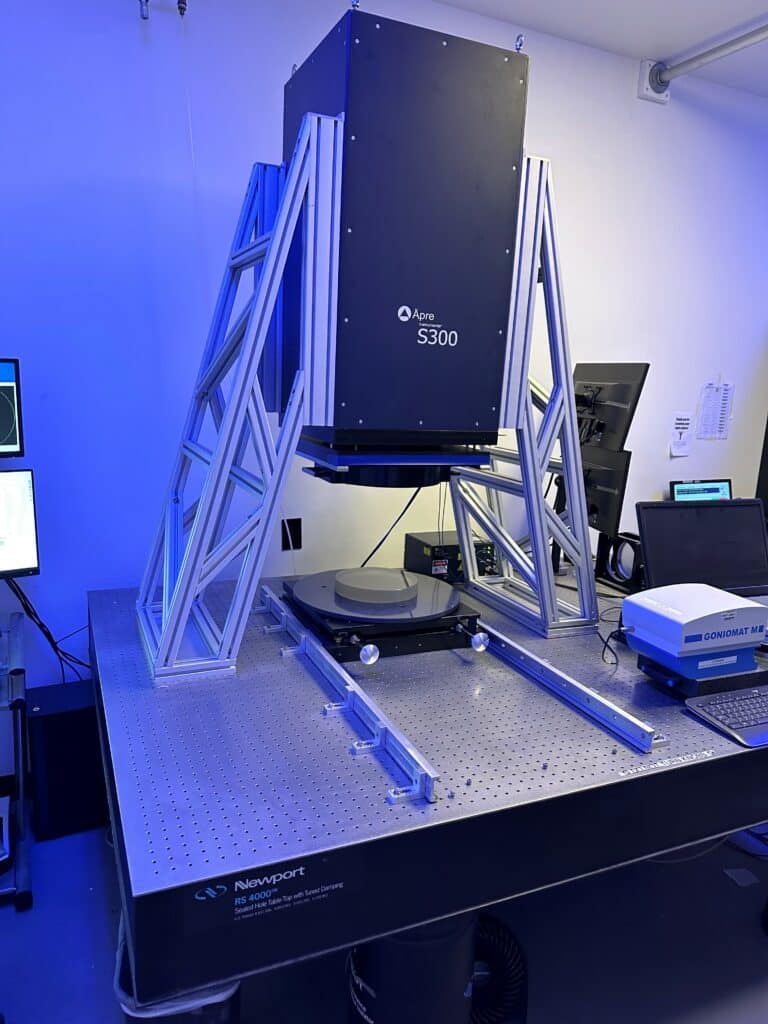

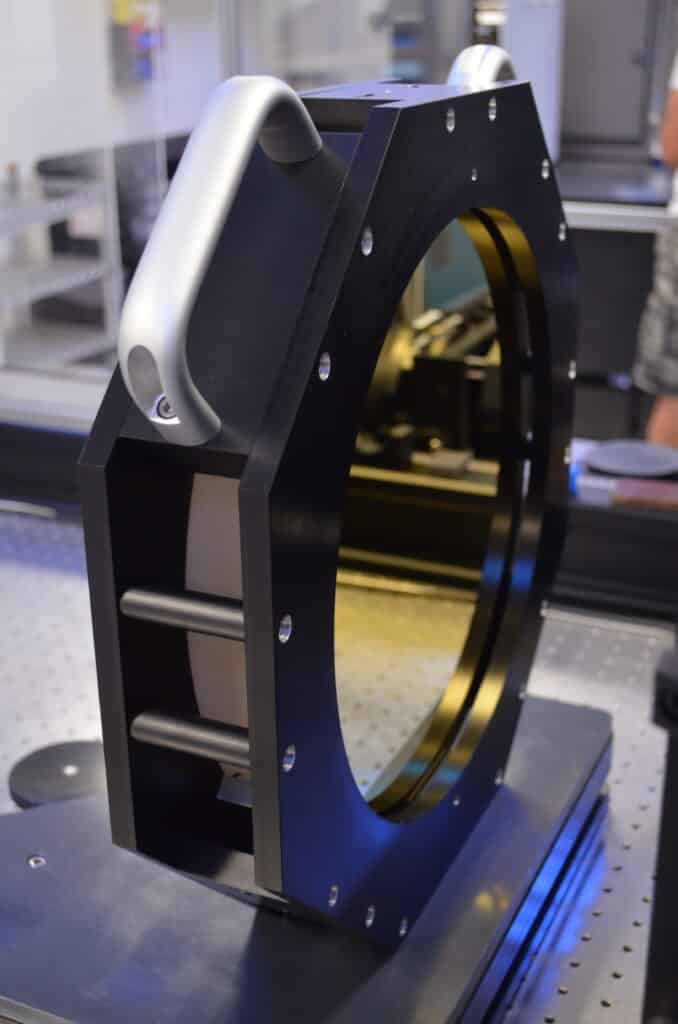

Precision Optical Celebrates 65 years of Optical Excellence. Precision Optical: our name embodies who we are. Since 1959, Precision Optical has earned a widely recognized reputation for reliability, value, and quality precision optics for the most demanding applications worldwide. An ISO 9001:2015 certified and ITAR-registered company, Precision Optical offers a diverse portfolio of capabilities for the prototyping and large-volume production of precision optical components for the biomedical, aerospace, defense, semiconductor, metrology and laser industries. These capabilities include optical fabrication, optical polishing, CNC Machining, opto-mechanical assembly, engineering and metrology services, and thin film coating. Key to Precision Optical’s success has been our commitment to expanding our capabilities in all areas of optical fabrication and metrology, giving us unsurpassed process control and flexibility in responding to customer requirements. Most recently, we have invested in a state-of-the-art 600mm laser interferometer, which allows us to inspect optics as large as 800mm and support large optic demand.

We have always strived for perfection, while continuously evolving and improving. We are family-owned and operated. By internal cross-training, internship offerings, partnering with local academia and our local chapter of OSA (OSSC) we are fully dedicated to maintaining a regenerative ecosystem of optics and photonics technicians, and are currently hiring in those areas.

Precision Optical is known for pushing the limits of optical manufacturing by satisfying ever-evolving customer demands and maintaining cutting edge metrological capabilities. Precision Optical provides the highest quality of precision optics available on the market and complements its products with dedicated and superior technical support for its customers across the globe. Please contact us at sales@precisionoptical.com, stop by Booth # 654 at the Moscone Center, San Francisco, CA, Photonics West 2024 or visit our website at www.precisionoptical.com. Nicolaus Lambert (President & CTO), Jeremy Gordon (Vice President Sales & CRO), and James McClure (Sales Manager) will be on site throughout the week (Tuesday January 30th through Thursday February 1st).